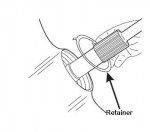

i just finished replacing all the seals on the propeller shaft on my 03 vp dps-m 1.95. on page 212 of the workshop manual it states to adjust the spanner tool to achieve a rolling torque of 18-26in lb with the spline socket on the driveshaft. i have the retaining ring very tight with the spanner tool and could only get a rolling torque of 13-14 in.lb i am afraid to put any more pressure on the spanner tool to get it any tighter. is 13-14ok? Thanks - Ryan

after posting i went back to it again, the retaining ring is fully seated. (threads bottomed). and the initial breakaway force is 17in.lb. once rolling 13 in.lbs. the only thing i have done is removed the propeller shaft housing and replace the shaft seals. actually the shaft seems to spin about the same as before (by feel) i would think that 26 in lbs would be way to much force.- any ideas?

after posting i went back to it again, the retaining ring is fully seated. (threads bottomed). and the initial breakaway force is 17in.lb. once rolling 13 in.lbs. the only thing i have done is removed the propeller shaft housing and replace the shaft seals. actually the shaft seems to spin about the same as before (by feel) i would think that 26 in lbs would be way to much force.- any ideas?