dbrannon79

Seaman Apprentice

- Joined

- Jul 22, 2009

- Messages

- 36

Hi to yall, I'm new here. I started repairing my 61' tri-hull boat and found that all of the transom and portions of the floor were rotten. I have since installed a new transom board consisting of 3 layers of 1/2" plywood which I coated very well with fiberglass resin. I installed the new transom and sat the top half of the boat back on the lower hull. all of the pop-rivet holes are lined up where the "bumper" molding surrounded the boat. I need to know what kind of sealer to use to fill the gaps between the top of the new transom and the upper part of the hull. I have included some snap shots of what I'm talking about.

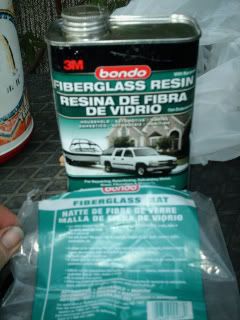

before I pulled the original transom the gaps were filled with bondo. is that good to use. keep in mind, I'm on a tight budget!

oh and one more question. there were two drain holes in the top of the transom that had some kind of metal sleeve through the transom. in the last pic it shows where one of them was. where can I find them at, or what do I use to replace them?

Thanks.

before I pulled the original transom the gaps were filled with bondo. is that good to use. keep in mind, I'm on a tight budget!

oh and one more question. there were two drain holes in the top of the transom that had some kind of metal sleeve through the transom. in the last pic it shows where one of them was. where can I find them at, or what do I use to replace them?

Thanks.