Re: help with valves,i think

Those drill pumps are free to borrow at most auto parts. Do the reading on how to set the valve lash.

I'd recommend pulling the distributor cap first, if the rotor is pointing at #1 do the static adjustments for the appropriate valves right then, and conversely for the others if it's aimed at #6. Otherwise just back them off before turning the crankshaft just in case there is a valve against a piston.

The reason the motor turned and you didn't hear or feel any compression resistance is because the valves were adjusted so tight that they did not close all the way.

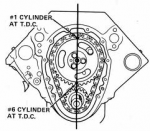

I'd put the motor at #1 top dead center, loosen all the valves til the pushrods can spin between two fingers, mark & pull the distributor, run the oil pump off the drill pump tool, adjust the first 8 valves, put the distributor back in at #1, turn the crankshaft one revolution which puts the rotor at # 6, and adjust the rest of the valves.

You can save some time if you note the orientation of the oil pump slot on the distributor when you first remove it. If you put the oil pump back at the same angle when you are done priming the lifters, it makes it easier to stab the distributor at the right tooth.

If the motor is out and the front cover is off you can just watch the cam and crankshaft marks to get things to the right spots.

I hope your friend didn't cause any valve to piston contact. I'd verify with a compression test once it's assembled. When normally adjusted the Chevy pistons don't hit the valves. But yours was way over adjusted, I hope nothing touched!