- Joined

- Jul 18, 2011

- Messages

- 18,946

Ribs, gussets, and bolts. . . .

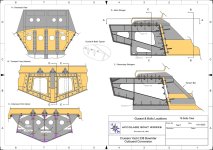

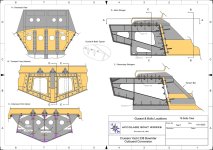

While away, I did some detailed drawings of the extension pod and support structure. Yellow is the boat's structure and gray is the extension pod and support structure.

.

.

I am going to add a bunch of gussets to support many of the flange areas where the bolts will go. Some ribs to stiffen the long horizontal runs, . . . and lots of bolts, distributing the load.

In total there will be 74 gussets, 16 ribs, and 78 bolts. Since there are so many bolts planned, I am thinking 3/8" fine thread hardware (316 SS).

While away, I did some detailed drawings of the extension pod and support structure. Yellow is the boat's structure and gray is the extension pod and support structure.

.

.

I am going to add a bunch of gussets to support many of the flange areas where the bolts will go. Some ribs to stiffen the long horizontal runs, . . . and lots of bolts, distributing the load.

In total there will be 74 gussets, 16 ribs, and 78 bolts. Since there are so many bolts planned, I am thinking 3/8" fine thread hardware (316 SS).