Re: Inboard outboard air cooled engine

Good'nuff! Continue with plan "A"...

We can use my idea as plan "B"..as we are doing a "cheap as possible" here, with whats available.

I'll have to go back and re-read all the post. Seems on track so far.

That little boat of my dads was real simple. Fired, and off ya went. I would not get to complicated here. I would NOT worry much about any oil drain. I just have a Harbor Freight Suction gun (similar to a grease gun, only works reverse, just pull the handle. I stuff it in the oil fill hole, suck the old (I had to put a smaller diameter hose in the inside on the stock large one..). Suck it out, then fresh..good nuff. I have too many small motors, and aint pulled a plug in years. Have a 70 Snapper 5hp rider mower. Still runs STRONG..cuts foot grass, and maybe did a good drain 5 times, (like every 5 years!)

Exhaust...simple pipe..run it anyway ya want. Long pipe hurts nothing...probably add torque. We aint talking some high RPM motor here.

I been messing with stuff like this (minibikes/Karts) since 1960. at it 50 years now. ..I'm 57, soon 58. 7 bikes, 4 boats, motors everywhere. Ended up doing 21 years as a Maintenance Machinist..retired in 94 with a plant close down, and I had age and time in for the pension..yep, lucky!

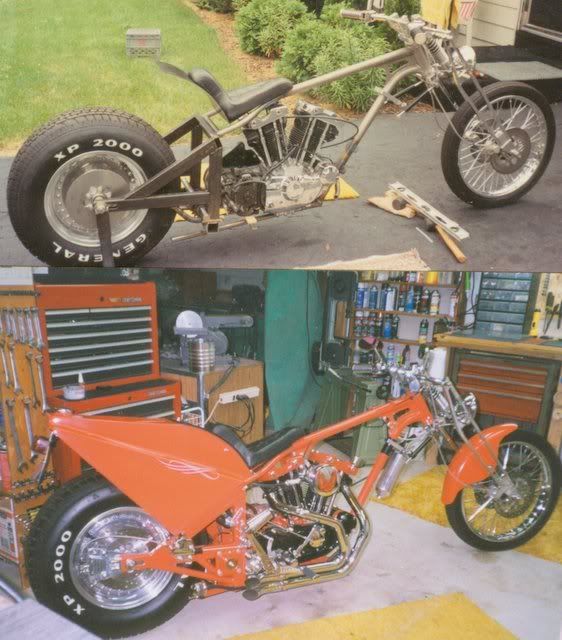

I started a Harley Dragbike "Look a like" project a LONG time ago. 1991. Wanted to make it street-able though.

Started with a old Honda inline 4 "chopper" frame from the 70's. Sawed the whole back off, stuffed a Harley Sportster motor in, jack shaft, solid rear end, 220 car tire on a car rim. Polished both sides 'Centerline" aluminum rim, with home made hub's. 6 foot long chopper front end cut down, a rear wheel hub was spooled on a front wheel, as I needed the both sides of a rear Harley hub for dual disc brakes. Made all the brackets for mounting the brakes.

Good LORD, the THINKING needed! 1991..probably 4000 hours total, still needs fine tuning. I had to BUILD everything. Most stuff was not sold then, not like the bigshot loudmouths on TV now, that just bolt stuff together.

Out in the shop now on the laptop..I get back in the house, I'll do a pic of it. Kept it simple as possible, and cheap as possible.

And have a ball doing it.

I spend a LOT of time..wandering the aisles in Home Depot..just looking at stuff that can be used for anything but whats its intended more...gotta "tinker"!

And ya gotta think....the kid still involved in this project?...great learning ..stuff not taught in ANY school ..fun to get the old brain "smoking"..

I'll have to reread all this, but a quickie says don't worry to much on the drive...try what ya came up with...not a lot of "force" involved spinning a prop in water, as compared to "force" needed to drive some 200/300 pounds of metal and the also 200 pounds of the fat rear end connected to me, all going to a small tire patch. That breaks stuff .

Have fun with this....if needed, go ahead and PM me on any question. Ya want, toss ya a phone # too...be glad to help. Robby..(still at it, and refuse to grow up....(kinda like it when I crack up the neighbors when I come down the street (we are a private HOA waterfront)..on something like the latest dirtbike. Its only a 2hp now..maybe does 20mph tops. Damn kids come by and pass me on mini's, or Quads...laughing. Then I switch to one of my Harleys...track'em down! Lots of fun!

Have fun with this..