cfauvel

Chief Petty Officer

- Joined

- Aug 16, 2005

- Messages

- 645

actually I was thinking the same thing....the rubber check flapper could rip...so the piston would suck oil into the tiny chamber, but as the piston pushes back, it pushes the oil back into the oil-inlet tube.

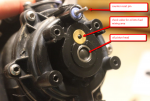

then the teeny tiny check valve that is the inlet for the oil to be mixed and push up on the pin COULD get clogged by debris....it is VERY small orifice.

so on that, I acquiesce , there could be a few conditions where there would be a no-oil condition.

then the teeny tiny check valve that is the inlet for the oil to be mixed and push up on the pin COULD get clogged by debris....it is VERY small orifice.

so on that, I acquiesce , there could be a few conditions where there would be a no-oil condition.