Re: Late 60s or Early 70s 15' bowrider - Admiral branded manufactured by "Fish-N-Ski"

Re: Late 60s or Early 70s 15' bowrider - Admiral branded manufactured by "Fish-N-Ski"

I'll preface this giant list by apologizing. I'm a geek. I work on computers for a living and I sometimes over analyze. I tend to research the heck out of things before I plunk down any significant amount of money. So far I'm only $300 into this boat. Budget is tight but I don't want to cut corners either. I have about $500 on hand to get me started and I can add to that as time goes by. I don't expect to have this done by June like my BIL, who has volunteered to help my out. If I splash this boat this summer at all I'll be a happy man.

1. Glassing. Is there some basic how to glass thread? Basic materials, tools, terminology type information in one thread I can read up on? Where can I get materials, respirator, tyvek suit, etc? Plus I saw this thread:

http://forums.iboats.com/showthread.php?t=304557&page=2 where special_kaye says

System Three Epoxy Resin and slow hardener. I love System Three. Notice no respirator? Don't need one with System Three.

Is this too good to be true? At my size, 6'6" 300lbs, I have a feeling finding a tyvek suit that fits could be challenging and expensive. Even if I get away without it when applying glass/resin, won't I still need it anyway when I'm sanding?

2. Trailer/support. There are 4 rollers on my trailer. Only 2 are making contact with the keel. I'm going to see if I can adjust them so they all bear some weight. The bunks seem like they are in the right place to provide support given the rollers are doing their part. I also need to figure out why the running lights only work on one side. Brake and turn lights work, but not the running lights on the right side. I'm sure the lights will be one of my last priorities.

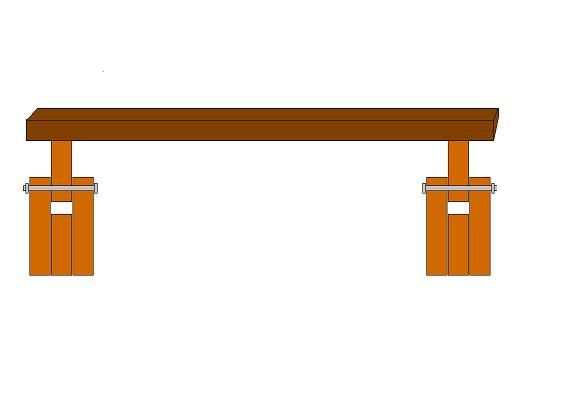

3. Cap/Splashwell. I need to either remove the cap or cut out the splashwell to replace the transom. There is a good 18-24" overhang making it very difficult to even peel back the floor covering stuff that is on the inside. When I did pull it back the inside skin of the transom started coming with it. I'm leaning toward cutting. I'm not confident I can remove the cap without breaking it nor that I can properly prevent the hull from changing shape while the cap is off. I'm worried my weight on the inside during repairs could cause permanent damage to the hull. I also do not want to build a custom wooden support for the boat to rest on during this process. Should I cut from the inside out, making the smallest overall cut into the sides of the cap, or should I cut from front to back to leave the sides more intact? As in attached pic

, Red line, Yellow, Green, or something else? Should I cut some 2x8s and lay them across the stringers to kneel on as I work just to make sure I don't damage the hull?

4. Transom. Once I get the the transom out is it feasable to glass a new inner skin before replacing the transom? I ask because I'd like to use seacast, nida-bond, or arjay 6011 for the transom but I'd like it to bond to both the outer and inner skin glass if possible. I know seacast makes 1.5" spacer blocks and strips to use to prevent the transom pour being to narrow/weak. If I could cut some thin pre-made glass board to fit, glass it in, and used the spacers to gap it properly, then I can pour in the transom as desired. That said, does anyone know of a distributor of nida-bond or arjay in Michigan? I found one listed for seacast and nida-core but the nida-core distributor doesn't look like they do much retail sales, just service work. I sent them an e-mail, along with an arjay distributor located in TN for quotes. I figured shipping from TN would be cheaper than shipping from the distributor in Florida arjay recommended originally. The seacast distributor is about an hour drive from me. They have a transom kit including: 5 Gallons of Seacast, Two 2.75 oz Tubes and One 1 oz Tube of BPO Catalyst, and 7lbs of reground fiberglass for $212. I took measurements and it looks like I'll need 7 gallons. It looks like it's available in 1 gallon buckets also. Might save a few bucks buying 5+1+1 or just buy two 5 gal and use the extra on the stringers if necessary.

5. Stringers. I'll verify but I'm pretty sure mine are hollow glass. Should I drill some holes and fill with seacast/Nida/arjay? I considered it to give better strength and to give the deck something to screw into. Perhaps the added weight won't be worth it. Do I need to tie them into the transom some how? Should I drill drain holes, tube them, seal, etc, to allow water to make it to the bilge easier?

6. Deck. My plan here was to use marine grade plywood. I know I can get away with exterior grade but most sources like this one:

http://www.plywood.cc/2008/08/09/marine-plywood-a-comparison-with-general-exterior-plywood/ say the marine grade glue is superior, has no voids in the laminations, uses better wood species, etc. I found a price nearby of $70/sheet. I'll only need two sheets. No matter which way I go I have concerns with how to attach the deck to my hollow glass stringers. If I fill them the concern lessens. I would also like to change the seet configuration as well. I'm leaning toward two pedestal chairs behind the windshield and a custom built bench in the rear rather than the pair of back-to-backs I removed. I know I can build a decent bench and get closed cell foam inexpensively. My concerns are finding inexpensive chairs/seats with decent height and not compromising my deck when attaching them. I thought if I had the chairs prior to deck install I could put stainless bolts up from underneath with a lock nut on the topside; glass over the bottom side and bolt head, before installing the deck. Obviously I'll glass over the top as well. I thought that might prevent seat mounts from compromising my deck. The other deck thoughts are that I don't want carpet. Seems the boat came with some kind of thin linoleum type plastic/rubber floor cover that was textured on top. I'm thinking once glassed in I'd like to just paint/coat it with something durable, textured, and waterproof.

7. Keel. I'm afraid some of the keel damage is underneath the fiberglass floored bow. If I have to remove the bow seats/floor section, I'll definitely have to pop the cap. Would my assumptions be correct that I need to glass inside repairs first, then outside, plus paint/gelcoat? Any how-to do threads for inside/outside keel repairs?

8. Paint/gelcoat. I'm thinking I'd like to repair the finish on the boat as well. If I'm going to cut the splashwell out and repair the keel, I'm going to want to make it look decent once those are patched up. I should be able to get my step-dad's air compressor. He inherited my grandfather's which has a smaller tank so he said I could have his larger one. I mention this since I've read gelcoats are best sprayed on. Is the same true for boat paint? What are the options, and pros/cons of each?

9. Windshield. It seems to be solidly mounted with no cracks in the glass. However the middle section doesn't close quite right. Also, the aluminum looks pretty dull/old, as do the bow rails. I'd like to make them look nice without having to replace them. I'm sure I can polish the glass itself to make it look better. Any suggestions for products/methods here are welcome. I figure I'll have to remove the windshield in order to flip the boat for keel repairs/paint or gelcoat.

10. Motor. Perhaps this is the most important item since it may be worth more than the boat at the moment. As far as I know it ran fine when put into storage. It had a mouse nest under the cover but I was unable to see any chewed wires or hoses. Everything looked great other than the nest I removed. I have not run it yet. I don't have the tool that allows the motor to run using my hose water to cool it. I won't put the boat in the water like it is nor would I trust the transom to hold it properly without causing more damage. I need to do a "reawakening" on it. I saw a basic thread describing the steps to bring it back to life. It seemed rather extensive but I know it'll be necessary at some point. Perhaps I'm being naive but I was planning on doing the motor after the boat was done. Either way I need to take it off the boat and I don't have any way to lift it or any stand to hang it on. What does a 1975 70hp Johnson weigh? If it's not too high could my BIL and I lift it off by hand? Is there some basic design for a stand I could build out of lumber that won't cost me a fortune? My BIL has volunteered to help me with this boat project. Maybe I'll have him work on the motor when he's here and I'll focus on the boat. He's decent with engines, not much better or worse than I am. Plus that way he won't necessarily need a tyvek suit, respirator, etc.

Again, sorry for the huge post, information dump, and littany of questions. These are the thoughts racing through my head ever since getting the boat home. If anyone replies don't feel it necessary to comment on all items. Any an all help will be greatly appreciated.

Thanks again,

Mike