chestypuller

Seaman Apprentice

- Joined

- Jul 12, 2014

- Messages

- 30

well here i picked up a flat bottom fishing boat for rivers, it has allot of character to say the least... included in the character is the dreaded 125 force from 1989 ive been reading so much about... with a blown headgasket on #3 piston ive revealed.

ordered the new headgasket and used head bolts since one broke( still need to drill the remainder out of the block)

Im a newbie, but this sure seems like a simple engine.

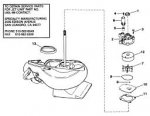

one question i have is, is the waterpump impeller for the cooling in the jet unit itself? and is it a different part number then the propeller version? i wanted to get one on the way but want to make sure its the right one before i have it shipped to Alaska.

ordered the new headgasket and used head bolts since one broke( still need to drill the remainder out of the block)

Im a newbie, but this sure seems like a simple engine.

one question i have is, is the waterpump impeller for the cooling in the jet unit itself? and is it a different part number then the propeller version? i wanted to get one on the way but want to make sure its the right one before i have it shipped to Alaska.