lundnisswa

Petty Officer 1st Class

- Joined

- Mar 2, 2008

- Messages

- 245

Re: Lund Nisswa Restoration

OOps,

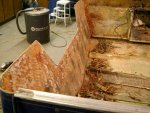

Pic #1/Post #18, in the lower right hand corner of photo, if this is the hairy stuff you are referring to, this is where I had cut the fiberglass fuel tank support piece out, (There is a little edge of the cut glass sticking up from the boat hull in the picture that I need to grind off, the tip of the pen is pointing to the delam/loose fiberglass at the keel rub point.

OH, yes, believe me I have read ondavr posts, and will read again, amazing what you guys are doing, the cutting the boat in half has kept me up late a few nights now reading that job. I am well versed with the search button.

Found a man here in town that is experienced in fiberglass boat repair, he is coming over tommorrow to take a look, I am hoping he may assist in the glassing job and mainly I will be learning alot from him.

I think I am making a bigger deal of the actual fiber glass application process than it may be, but I have seen shotty work before,

and I do not want to do a half A%$ job and have all the effort fall apart on me.

I posted 3 wider angle pictures that were taken from the same point as pic #1/post #18

Scott

N.D.

OOps,

Pic #1/Post #18, in the lower right hand corner of photo, if this is the hairy stuff you are referring to, this is where I had cut the fiberglass fuel tank support piece out, (There is a little edge of the cut glass sticking up from the boat hull in the picture that I need to grind off, the tip of the pen is pointing to the delam/loose fiberglass at the keel rub point.

OH, yes, believe me I have read ondavr posts, and will read again, amazing what you guys are doing, the cutting the boat in half has kept me up late a few nights now reading that job. I am well versed with the search button.

Found a man here in town that is experienced in fiberglass boat repair, he is coming over tommorrow to take a look, I am hoping he may assist in the glassing job and mainly I will be learning alot from him.

I think I am making a bigger deal of the actual fiber glass application process than it may be, but I have seen shotty work before,

and I do not want to do a half A%$ job and have all the effort fall apart on me.

I posted 3 wider angle pictures that were taken from the same point as pic #1/post #18

Scott

N.D.