achris

More fish than mountain goat

- Joined

- May 19, 2004

- Messages

- 27,468

That's the problem for reverse. Crud in the back of the bell housing will also mean crud inside the slide, and probably at the back of the slide cavity in the drive.

The bell housing and the drive cavity are (relatively) easy to clean. You'll likely have crud inside the slide, and you can not clean that without taking the core out, and taking the slide off the cable and cleaning all the way inside.

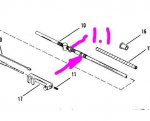

Referencing the diagram below...

Remove the locking wire from the end of the slide(17) and unwind the set-screw(11). At the shift plate end of the lower shift cable, remove it from the plate. Loosen (a turn each) the screws (14) locking the plastic guide (12) to the inner cable and remove the guide. From the outside of the boat, pull the slide out (it will bring the inner cable with it). Once it's all out, slide the slide off the cable and clean the inside of the slide.Inspect the end of the outer cable still in the bell housing and make sure everything is clean enough to eat off.

Once everything is clean to my standards , slide the slide back onto the inner cable and LOOSELY screw the set screw back in. Then give the inner cable a very light spray with silicone lubricant (yes, plenty here that will disagree with that, but hey, I've only been doing this for 25 years :facepalm: so what would I know...), and slide it back into the outer cable. Push it all the way in and then replace the plastic guide, making sure the core is visible through the sight hole at the anchor (13). You should see the core pass though that anchor. Now tighten the set screws (14) evenly. Not too tight, but tight enough for the cable not to slip. Back down at the bell housing, tighten the slide set screw until it JUST touches the end of the cable core, then back it off so you can get a new piece of lock wire through. The slide should be free to rotate on the core with a minimum of movement back and forth. Lock the set screw with the lock wire (any small diameter SS lock wire will do)...

, slide the slide back onto the inner cable and LOOSELY screw the set screw back in. Then give the inner cable a very light spray with silicone lubricant (yes, plenty here that will disagree with that, but hey, I've only been doing this for 25 years :facepalm: so what would I know...), and slide it back into the outer cable. Push it all the way in and then replace the plastic guide, making sure the core is visible through the sight hole at the anchor (13). You should see the core pass though that anchor. Now tighten the set screws (14) evenly. Not too tight, but tight enough for the cable not to slip. Back down at the bell housing, tighten the slide set screw until it JUST touches the end of the cable core, then back it off so you can get a new piece of lock wire through. The slide should be free to rotate on the core with a minimum of movement back and forth. Lock the set screw with the lock wire (any small diameter SS lock wire will do)...

Check the cable slides freely. Load the drive back on and go through the set up procedure, and don't forget to check the cable slop....

Chris........

The bell housing and the drive cavity are (relatively) easy to clean. You'll likely have crud inside the slide, and you can not clean that without taking the core out, and taking the slide off the cable and cleaning all the way inside.

Referencing the diagram below...

Remove the locking wire from the end of the slide(17) and unwind the set-screw(11). At the shift plate end of the lower shift cable, remove it from the plate. Loosen (a turn each) the screws (14) locking the plastic guide (12) to the inner cable and remove the guide. From the outside of the boat, pull the slide out (it will bring the inner cable with it). Once it's all out, slide the slide off the cable and clean the inside of the slide.Inspect the end of the outer cable still in the bell housing and make sure everything is clean enough to eat off.

Once everything is clean to my standards

Check the cable slides freely. Load the drive back on and go through the set up procedure, and don't forget to check the cable slop....

Chris........