.... So, my FIL suggested the timing may be a little advanced - making it run nice, but start hard.

So, I'll be looking at the timing here in the next week or so. ....

This is EXACTLY the time to change that distributor shaft position. Do you have a remote starter switch? (basically it's just a momentary switch (push button or 'press') with a couple of wires hanging off it. You hook the wires to the starter solenoid, one to red, one to red/yellow (doesn't matter which is where), and when you need to 'bump', the engine, just touch the switch.) Picture #1

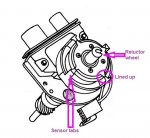

Removing the spark plugs (number the wires!) makes the 'bumping' easier and a bit more accurate. Remove the dissy cap, and bump the engine until the TDC marks line up, and the rotor is pointing at the (current) #1 terminal on the dissy cap. Mark the dissy body with relation to the engine block, and note where the sensor and reluctor wheel are (the reluctor wheel should be very close to the sensor tabs. Picture #2). Remove the clamp holding the distributor down, then lift the dissy straight up about an inch. That should disengage the gear from the camshaft. You will have noticed the rotor turn slightly as you lifted, that's correct. Turn the rotor 90

° CCW from it's current position. Now lower the dissy back into the block and you should feel it engage on the camshaft, and now the rotor will turn as you keep lowering, and then the dissy will stop (before being fully home). While holding the distributor to stop it turning (it won't be a great force) and applying slight down pressure, bump the engine with the starter switch until the dissy drops in (it's engaging the oil pump tab). That should take about 1/2 a turn of the crankshaft. The dissy body should be quite close to the previous alignment marks, so put the clamp back on and bump the engine some more to get it back to the timing marks lining up on compression stroke of #1 (finger over the hole trick. That should have taken 1-1/2 turns)... The rotor should now be pointing to the 'right' distributor cap terminal as per the book. Put the leads back on in the right places (each moved one place CCW). Start the engine and check the timing is roughly right, adjust if necessary, and let the engine warm up. Then go though the timing procedure as per your engine number and spec. I think for your engine it should be 2

° ATDC, with the distributor in 'base' mode. Do you have a copy of the correct timing procedure?

I know that looks a lot, but it's really not. As I said, about 3 minutes work.

Chris............

Remote starter switch

)

)