Not rocket science.

Move the boat back (and winch stand) an inch. The outdrive should be in a better position. If the tongue weight is too light now, leave the boat where it is. The OD is going to be up when traveling anyway, so it won't matter.

That boat does not need electric brakes. With your truck don't over-complicate things. You have a capable truck.

I can't climb in my boat either, so I bought a light weight plastic step ladder. Problem solved. The other option is to install a transom ladder, or use an after-market hang-on boarding ladder.

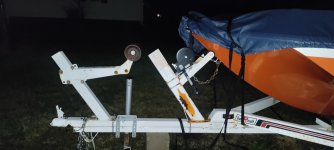

I don't readily see a problem with the winch stand from the pics. It looks like it is adjusted perfectly. If it is damaged, buy a new one. Lots to chose from online from the various trailer parts companies. Buy new, not an old rusty one from ebay.

Not pointing a finger, but please read the original post again.

The crux of the issue is that this trailer was likely designed for a 17ft minimum length... but this trailer happens to be what the marina had to trade for the original trailer that also fit the needs of the original owner.

Just because the current setup worked for 48 years doesn't necessarily make it right or in any case make it ideal. But, it's possible to rework the trailer to better handle my 16' hull without having to replace the whole thing, so when such a replacement turned into a boondoggle, reworking the trailer is the direction I'm opting to go.

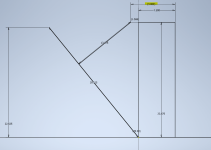

The winch stand literally cannot move further back... it's at the limit of it's travel:

Likewise, the entire fender/leaf spring/axle assembly is attached to the frame with U-bolts (fully adjustable). So, however far I move the boat, I can also move the assembly to keep the tongue weight consistent. Ditto for the front keel roller.

One of my concerns is that the bunks are seeing excessive load due to the transom being past the rearmost bunk supports. Also, any bit I can move the boat backwards is less deep I need to back the trailer to launch. Hasn't been an issue other than the one bunk rotting to pieces last season due to pitot tube damage from the excessive bunk stickout. Still don't like it.

So, the plan is to install the new winch stand (see below) so the current position is maintained (with gap between the stand and the upper tube end); once the boat is on the water on a future outing, I'll move the stand and axle assemblies on shore (no boat weight). Ideally 9", which puts the transom just past the end of the inner bunks (and a bit further past the outer bunks) and with the transom straps at the correct angle (pulling the boat into the bow roller, not away from it as is current).

My 1984 F150's brakes are not all that great (even with everything in working order)... I did fry the fronts last season. This generation of F-series (Chevy of this vintage too) are known to have brakes that leave a lot to be desired.

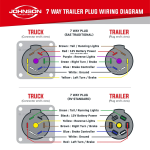

Yes, with a bigger/newer truck with better brakes, trailer brakes wouldn't be warranted... but, since I already have flanges for brakes on the current axle and my truck already has a good brake controller and a fully wired 7-way connection, I see not adding such brakes as a relatively low hanging fruit, and a lot less expense than changing trucks.

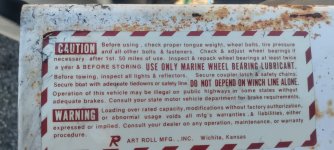

I don't know what the GVW of the boat and trailer actually is... the max GVW of the trailer is just over 3000lb (IIRC around 2600lb max boat/gear weight per the trailer tag). As for the boat itself, JD power says 1500lb, but I don't know which engine option that's for (I have a mercruiser 888 302, the heaviest option offered- the engine alone is reportedly 460lb per Ford). Some jurisdictions (Ohio, for example) require brakes on 3000lb... while the limit in Indiana is 3500lb, I figure it can't hurt and several people I know personally agreed that brakes wouldn't be a terrible idea.

----

I'll be driving up Friday to look at the boat winch/stand in my last post. I was able to get some more information on it... the orange junk in the pic is dirt from sitting in a gravel lot behind the guy's shop. Certainly looks beefy enough (beefier than the new option I posted previously). And the measurements do check out (should be able to get the full 9" I want). Yes, it is used. But I already have a virtually new winch to swap (that nasty old winch is going to the scrap pile)... and if the structural steel is solid (not rotted out) and not mangled, then good as new for my purposes.