runninfarmer

Petty Officer 2nd Class

- Joined

- Jun 28, 2012

- Messages

- 124

This is my first time posting on iboats, but I figured I'd share a project of mine. I recently acquired a partially restored 1988 19' Blue Fin with 2.3 OMC Cobra for $700. I like outboards though and didn't want to mess with the cobra, especially since their defunct now. I pulled the motor and all outdrive components and sold them for $500 quickly. Once I had them out I went searching for a bracket. I found right away the brackets are anywhere from $700 to $1500! Too much for my blood. This was a dilemma. After some deliberation and inspiration I designed one and decided to build one from scratch using 6061 angle aluminum and aluminum flat bar, with no welder. I bought a cheap $65 drill press from Harbor Freight and ordered the $450 worth of aluminum. That included all aluminum for the bracket, and plates/knee braces for transom reinforcment for the inside. Most commercial brackets don't come with that !

!

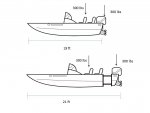

I'm about 30 hours into it and mostly done. Since the bracket is a paraellogram, it is fully adjustable, capable of adjusting to any transom angle. Will work with 25" and 20" shaft motors. I just have a couple more vertical members for the bracket to fabricate. I had to rebuild the transom, since it wasn't worth patching the old rotten one. Here are some pics:

I'm about 30 hours into it and mostly done. Since the bracket is a paraellogram, it is fully adjustable, capable of adjusting to any transom angle. Will work with 25" and 20" shaft motors. I just have a couple more vertical members for the bracket to fabricate. I had to rebuild the transom, since it wasn't worth patching the old rotten one. Here are some pics: