runninfarmer

Petty Officer 2nd Class

- Joined

- Jun 28, 2012

- Messages

- 140

Re: My Custom Offshore Bracket: I/O Conversion for less than $500, No Welder Required

Prolly a good idea to put diagonal members in. I have extra angle to do it, just have to take a breather on it for a while, lol. Been going hard at it for a couple weeks. I don't think it's physically possible for it to collapse with the way I have it, unless there is a failure at the middle members. But the suggestion is noted.

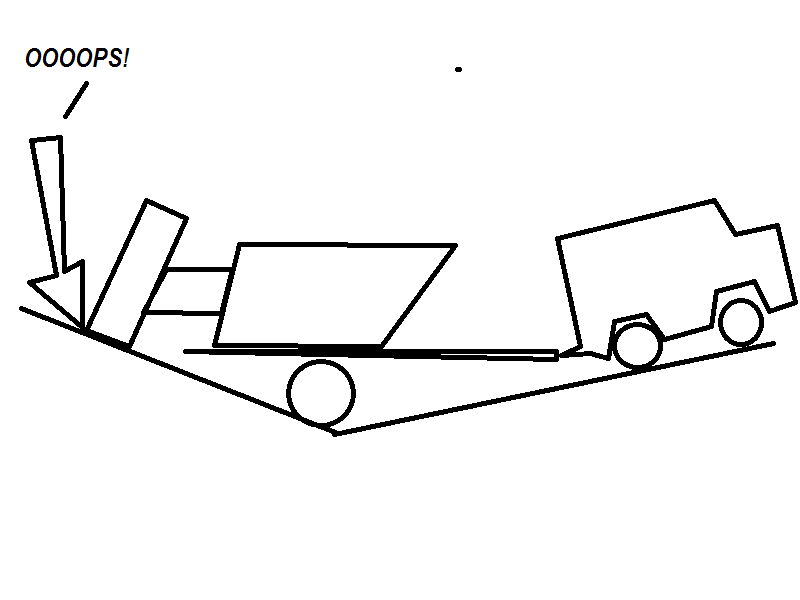

Have you considered something like this? You mentioned that you would like something adjustable. The white and green pieces have holes drilled in them, and you could raise or lower the drive by adjusting the bolt holes on those two pieces. Use two bolts in the middle spaced apart attaching the white and green pieces so they don't collapse. This orientation would also make it overall more rigid. Just a suggestion.

View attachment 194617

Prolly a good idea to put diagonal members in. I have extra angle to do it, just have to take a breather on it for a while, lol. Been going hard at it for a couple weeks. I don't think it's physically possible for it to collapse with the way I have it, unless there is a failure at the middle members. But the suggestion is noted.