BillaVista

Petty Officer 1st Class

- Joined

- Jul 1, 2013

- Messages

- 204

I've discovered my engine-mount bolt pattern is all screwed up. It's a '79 Johnson Seahorse 55 on 14' aluminum runabout. First the pic:

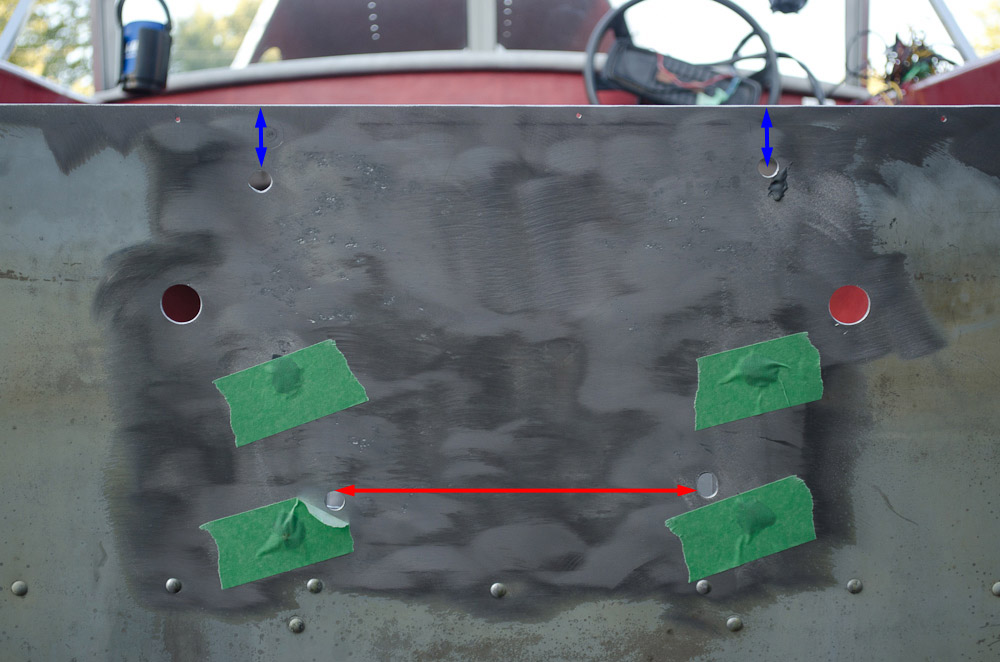

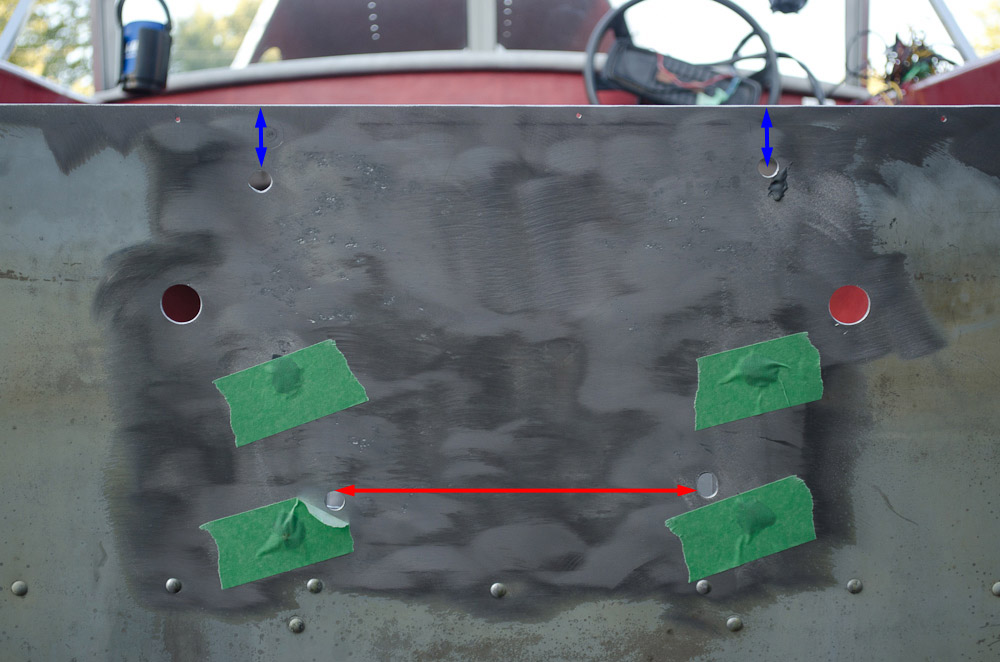

The top holes - the Stbd is 3/8" higher on the transom than the port (the blue arrows in the pic are exactly the same length). This means the motor was installed with a permanent list to port. The lower holes are similarly asker (the red arrow is horizontal), and you can see the lower stbd hole is badly ovaled.

I assume there's no valid reason to install the motor with a list to port? Therefore, I'm going to have to correct this.

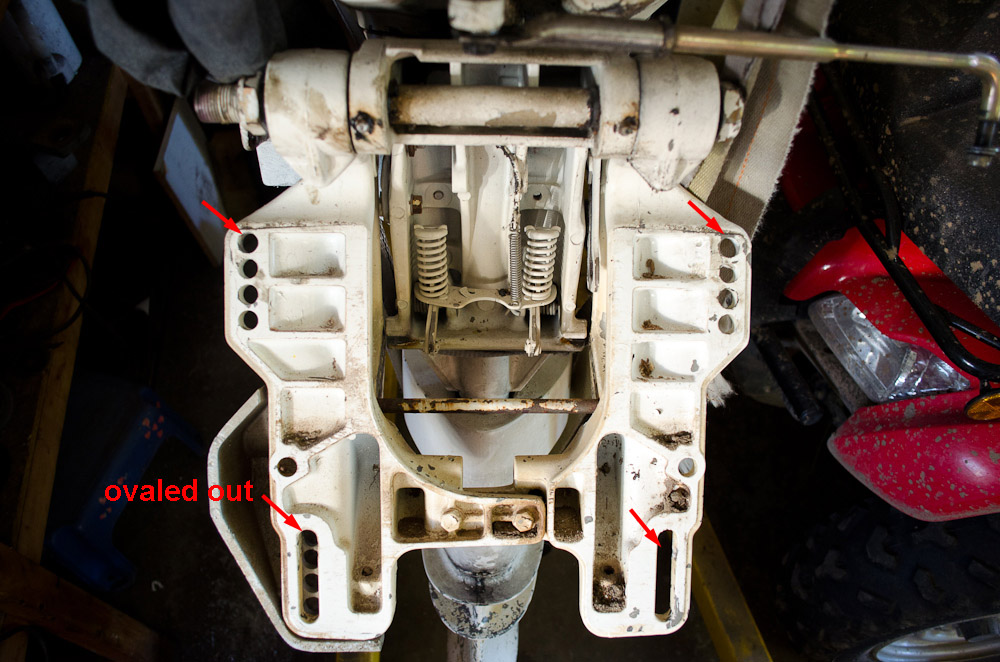

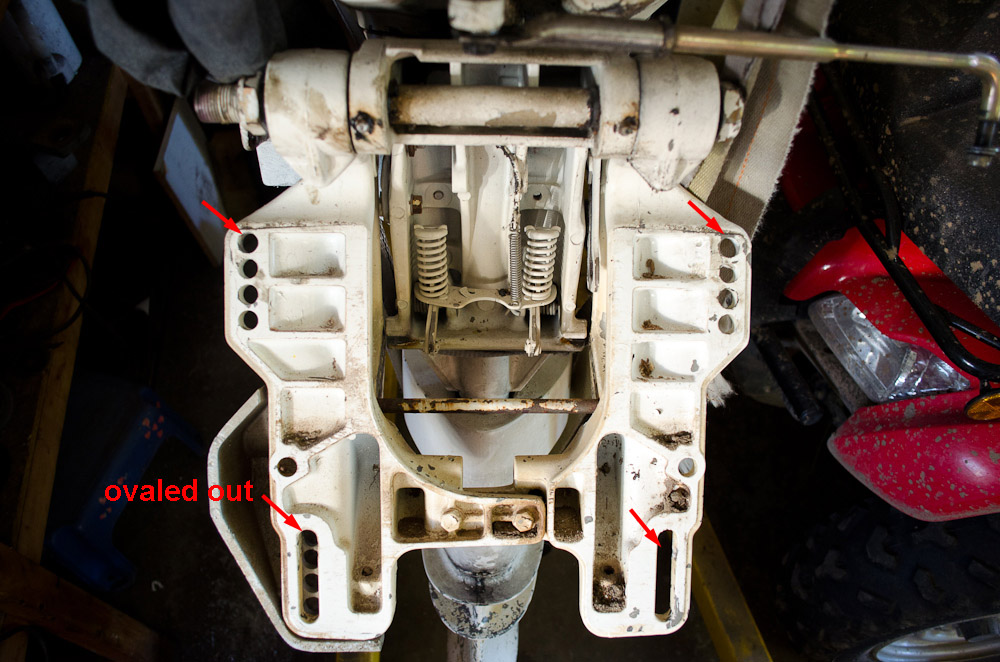

This pic shows the original mount holes used on the motor bracket (note the lower stbd hole has also been ovaled)

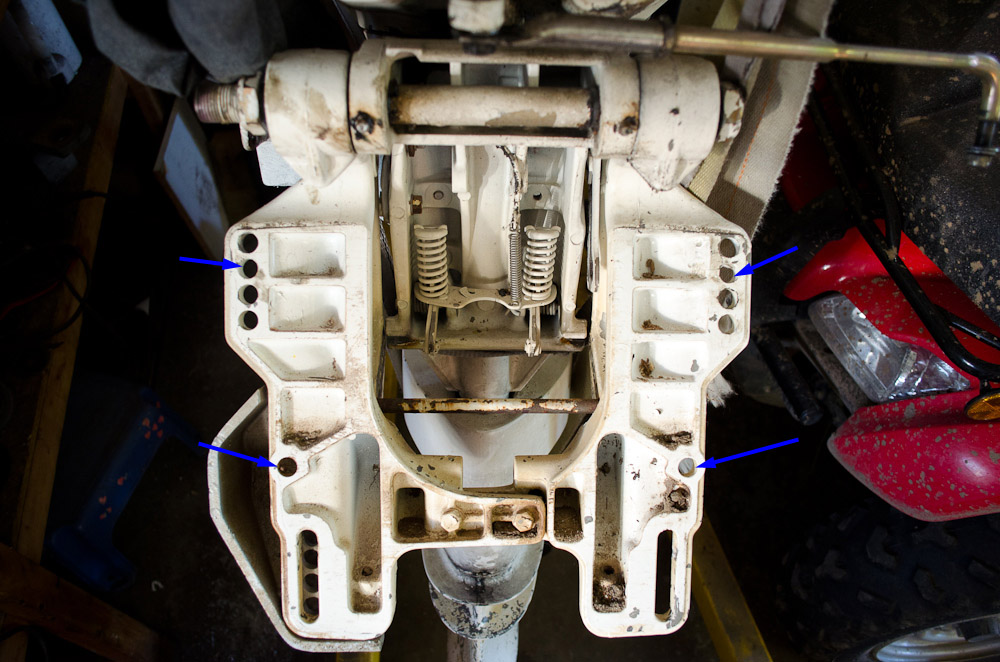

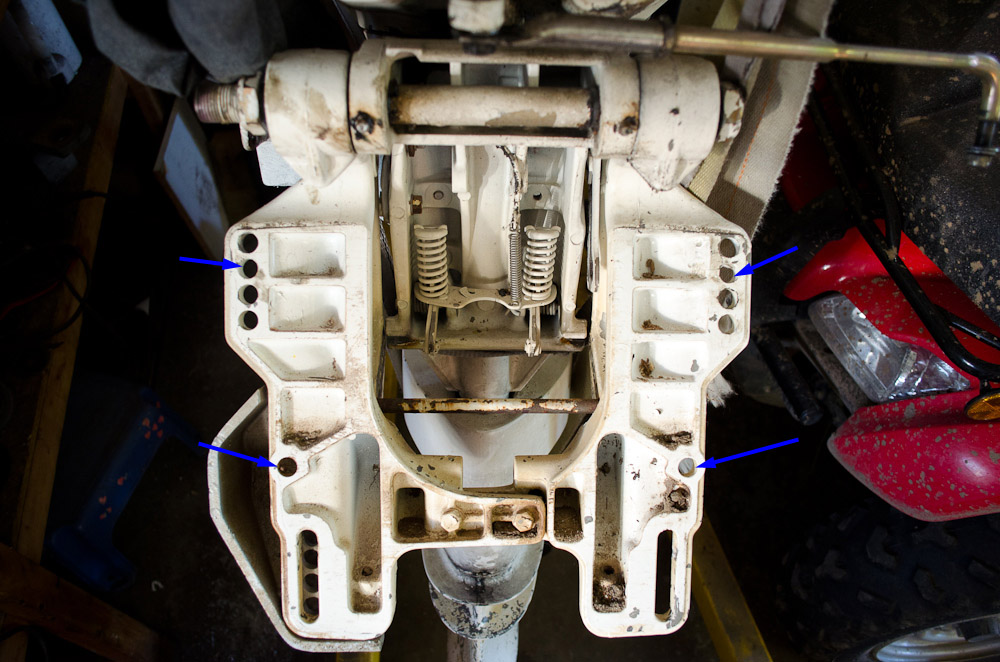

I would like to patch and fill the original holes in the transom, and use these mounting holes instead (blue arrows):

Is there any reason I shouldn't do this or any major drawbacks to doing so? Obviously, the bolt "spread" will be less, which isn't ideal - but will it be ok?

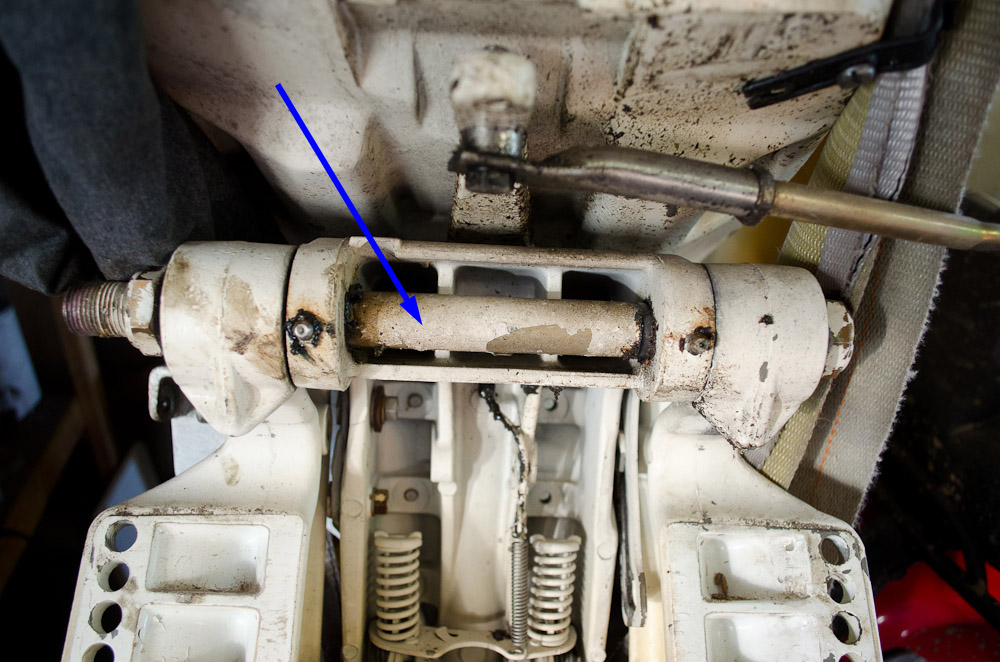

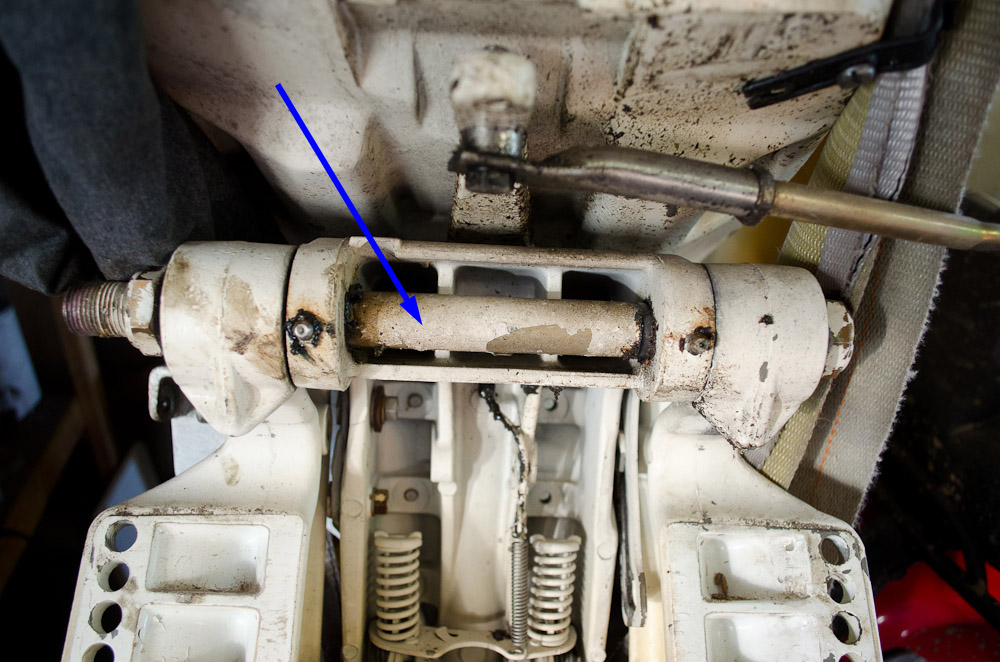

Finally - to do an accurate and neat job I'd really prefer to take the bracket off the motor and clamp it to the transom to drill the new holes (rather than transfer the pattern from bracket to a template then from template to transom - too much chance for error). But in order to do what I want and get the bracket off - I have to remove the steering tube thing (blue arrow) - any easy way to do this?

Thanks all for you help.

The top holes - the Stbd is 3/8" higher on the transom than the port (the blue arrows in the pic are exactly the same length). This means the motor was installed with a permanent list to port. The lower holes are similarly asker (the red arrow is horizontal), and you can see the lower stbd hole is badly ovaled.

I assume there's no valid reason to install the motor with a list to port? Therefore, I'm going to have to correct this.

This pic shows the original mount holes used on the motor bracket (note the lower stbd hole has also been ovaled)

I would like to patch and fill the original holes in the transom, and use these mounting holes instead (blue arrows):

Is there any reason I shouldn't do this or any major drawbacks to doing so? Obviously, the bolt "spread" will be less, which isn't ideal - but will it be ok?

Finally - to do an accurate and neat job I'd really prefer to take the bracket off the motor and clamp it to the transom to drill the new holes (rather than transfer the pattern from bracket to a template then from template to transom - too much chance for error). But in order to do what I want and get the bracket off - I have to remove the steering tube thing (blue arrow) - any easy way to do this?

Thanks all for you help.