drewpster

Commander

- Joined

- Oct 17, 2006

- Messages

- 2,059

Re: My tri-hull transom replacement w/ pics

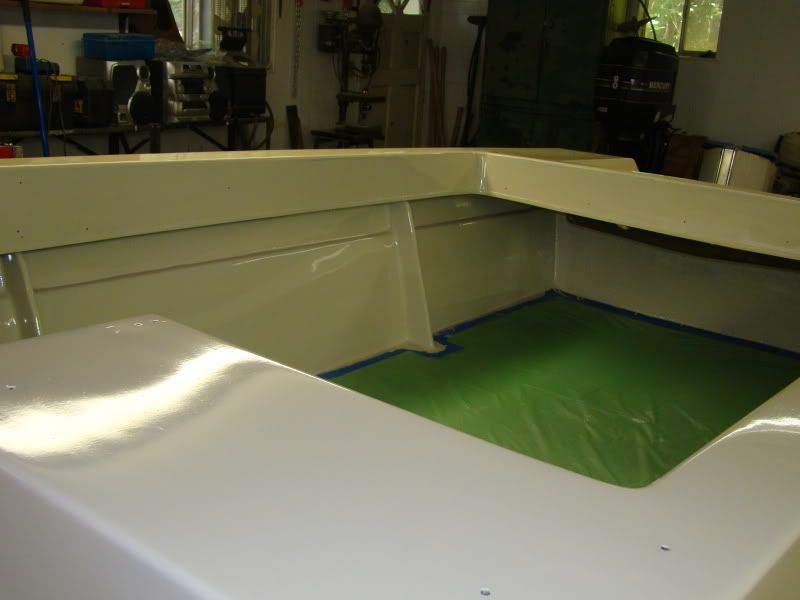

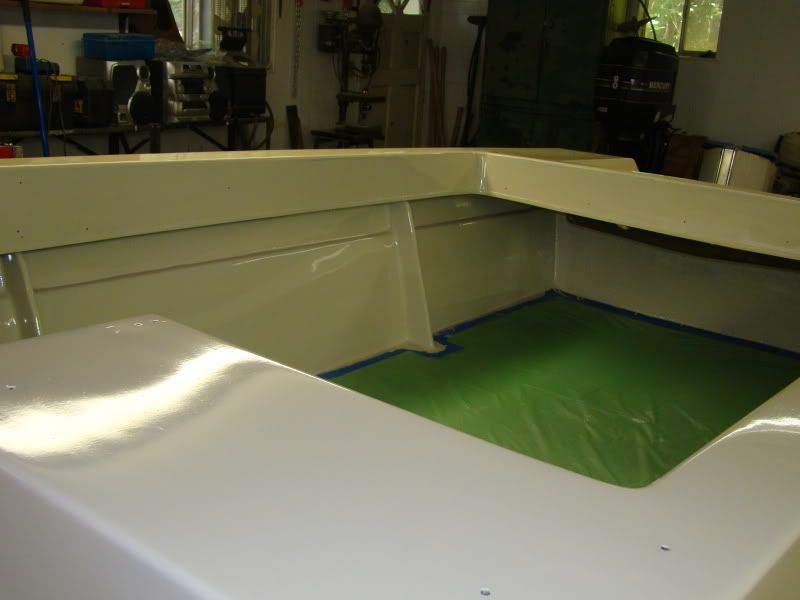

I ran out of paint before I could get the strip done around the outside of the hull. All of this was done with a single quart of paint. I blame my wife, she ordered the paint. (you did it honey, not me

I ran out of paint before I could get the strip done around the outside of the hull. All of this was done with a single quart of paint. I blame my wife, she ordered the paint. (you did it honey, not me  ) But I have another quart coming Tuesday.

) But I have another quart coming Tuesday.

One major challenge when working with this paint is keeping dust and dirt out of it while it is curing. It takes time for the paint to cure and anything floating or flying (bugs) will get in it. I took great pains cleaning the shop out as best as I could before starting. I left a box fan on low blowing out of the room through a screened window in the back of the shop. My shop is built in to a hill so it stays pretty cool regardless of the out side temps. It was around 78 degrees in the shop when I did the job. The humidity was high as always in Tennessee but it seemed not to have an ill effect on anything. I kept the doors closed and only opened them to leave after I was done. There is a bare minimum of defects, but there are some. This is not a paint booth. The only way I could have done better would be to hang plastic around the boat and vent it somehow with a fan. I also considered making some filters out of HVAC filters to cover the open windows at one end of the shop. Then vent it by using box fans in the windows at the other end. My concern is that my filter system would not remove all the mess out of the air stream. I would end up pulling dirty air and dust all over it. Still thinking about it though.

Even without all the filters and fans I am pretty happy with the way it came out. I will have to sand this for the next coat but it will be worth it.

BTW! Another thing to remember with this paint is the induction time. Be sure you let it sit about 20 minutes after you mix it. As the hardener starts the reaction, bubbles form in the paint. You need to let these dissipate before you apply it. Even after waiting a full 20 minutes at this temperature I had plenty of time to apply half the quart. I only mixed on half a quart at a time. The paint started to get just a bit "sticky" at the end of the half quart. I think a whole quart would have been pushing it especially working alone.

If you don?t let it bubble out, it can bubble on the surface. Thankfully I did not have that problem on the cream. The blue was another story. But I got that fixed.

Overall we are very happy. I am looking forward to getting the final coat on. After that I am going to put another coat of gelcoat on the deck. Then I'm done!!!!! wait........ i still have to put the thing back together. Ahhh the fun continues.

One major challenge when working with this paint is keeping dust and dirt out of it while it is curing. It takes time for the paint to cure and anything floating or flying (bugs) will get in it. I took great pains cleaning the shop out as best as I could before starting. I left a box fan on low blowing out of the room through a screened window in the back of the shop. My shop is built in to a hill so it stays pretty cool regardless of the out side temps. It was around 78 degrees in the shop when I did the job. The humidity was high as always in Tennessee but it seemed not to have an ill effect on anything. I kept the doors closed and only opened them to leave after I was done. There is a bare minimum of defects, but there are some. This is not a paint booth. The only way I could have done better would be to hang plastic around the boat and vent it somehow with a fan. I also considered making some filters out of HVAC filters to cover the open windows at one end of the shop. Then vent it by using box fans in the windows at the other end. My concern is that my filter system would not remove all the mess out of the air stream. I would end up pulling dirty air and dust all over it. Still thinking about it though.

Even without all the filters and fans I am pretty happy with the way it came out. I will have to sand this for the next coat but it will be worth it.

BTW! Another thing to remember with this paint is the induction time. Be sure you let it sit about 20 minutes after you mix it. As the hardener starts the reaction, bubbles form in the paint. You need to let these dissipate before you apply it. Even after waiting a full 20 minutes at this temperature I had plenty of time to apply half the quart. I only mixed on half a quart at a time. The paint started to get just a bit "sticky" at the end of the half quart. I think a whole quart would have been pushing it especially working alone.

If you don?t let it bubble out, it can bubble on the surface. Thankfully I did not have that problem on the cream. The blue was another story. But I got that fixed.

Overall we are very happy. I am looking forward to getting the final coat on. After that I am going to put another coat of gelcoat on the deck. Then I'm done!!!!! wait........ i still have to put the thing back together. Ahhh the fun continues.