I recently purchased a 1989 Four Winns 315 Vista from a liquidator and I'm restoring it. There are 2 blowers in the engine compartment that are disconnected and I need some guidance to replace and install them with new hoses as some things do not make sense to me. I will post pictures tomorrow.

Here's the scenario:

1. Should both blowers be located on one side?

2. Should both blowers be exhausting or, should one be drawing in air? And, if the latter, how should the hoses be configured?

3. Should the hose connected to the blower be from the front of the engine or the rear? (Assuming at the lowest point in the bilge?)

Thanks!

Frank

Here's the scenario:

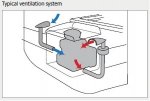

- There are four vent holes on both the port and starboard sides that the 4" hose are attached to (8 in total). Two of the hoses, on each side, laid at the back of the engines in the bilge. one of the hoses on each side laid at the front of each engine. The other two hoses (one on each side) were just laying in the compartment. No hoses were connected to the two blowers.

- Both blowers were mounted on the port side bulkhead.

1. Should both blowers be located on one side?

2. Should both blowers be exhausting or, should one be drawing in air? And, if the latter, how should the hoses be configured?

3. Should the hose connected to the blower be from the front of the engine or the rear? (Assuming at the lowest point in the bilge?)

Thanks!

Frank

Last edited: