Hello all.

I recently had to have the tilt arm shaft and a couple of other small pieces replaced on my Honda BF25 as they were damaged during trailering (speed bump). I felt I got soaked on that one from the shop based on what they charged me for the parts, and am reluctant to call them to discuss a current problem that I think may be related to the previous repair work.

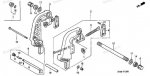

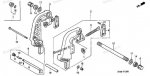

Ever since the tilt arm shaft was replaced it is now way more difficult to raise the motor (manual tilt). When not running, it is still way more difficult to lift the motor even when on the trailer. I was wondering if it could be related to the shop over-tightening either the tilting shaft nut (part 14 on attached figure) or the hex bolt (part 13 on the attached figure) during their repair work on the tilt arm shaft? Can I loosen these things up a bit without them working their way even looser while operating?

Any suggestions or comments are appreciated.

Thanks,

TDuff

I recently had to have the tilt arm shaft and a couple of other small pieces replaced on my Honda BF25 as they were damaged during trailering (speed bump). I felt I got soaked on that one from the shop based on what they charged me for the parts, and am reluctant to call them to discuss a current problem that I think may be related to the previous repair work.

Ever since the tilt arm shaft was replaced it is now way more difficult to raise the motor (manual tilt). When not running, it is still way more difficult to lift the motor even when on the trailer. I was wondering if it could be related to the shop over-tightening either the tilting shaft nut (part 14 on attached figure) or the hex bolt (part 13 on the attached figure) during their repair work on the tilt arm shaft? Can I loosen these things up a bit without them working their way even looser while operating?

Any suggestions or comments are appreciated.

Thanks,

TDuff