Re: Project Fishtoon

Thanks as always for this info.

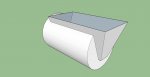

I'm really struggling with a transom section design that I think will withstand the weight of my Honda (487 lbs dry). If I understand you correctly, I think you are recommending a design similar to below but with additional 1/2" thick plates in lieu of the rectangle tube:

My main concern lies with tying the new transom tube section to the "old" unmodified tube. I'm wondering if a design similar to yours with a beefed up transom, as discussed (1/2" plate with square tube), as well as an internal square tube frame that runs from the transom to the untouched center pontoon.

With this design, the transom section would be connected to the old, long tube via 1) the internal frame, 2) the welded circumference where the two tubes meets, and 3) any strakes, top braces, or other horizontal additional framing added that overlays both the old and new tubes.

I realize that I'm junking up your thread with my ideas, so I'll start a new thread of my own if you promise to subscribe to it and help out when possible! Thanks!

Thanks!

Thanks as always for this info.

I'm really struggling with a transom section design that I think will withstand the weight of my Honda (487 lbs dry). If I understand you correctly, I think you are recommending a design similar to below but with additional 1/2" thick plates in lieu of the rectangle tube:

My main concern lies with tying the new transom tube section to the "old" unmodified tube. I'm wondering if a design similar to yours with a beefed up transom, as discussed (1/2" plate with square tube), as well as an internal square tube frame that runs from the transom to the untouched center pontoon.

With this design, the transom section would be connected to the old, long tube via 1) the internal frame, 2) the welded circumference where the two tubes meets, and 3) any strakes, top braces, or other horizontal additional framing added that overlays both the old and new tubes.

I realize that I'm junking up your thread with my ideas, so I'll start a new thread of my own if you promise to subscribe to it and help out when possible!