Tnstratofam

Commander

- Joined

- Aug 18, 2013

- Messages

- 2,679

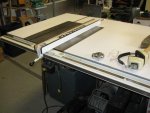

Here are some pics of the Crafstman. I would like to fix it up if it's worth it. If not surely all that cast iron is worth something to somebody.

In the last picture you can see the top needs some attention. What should I do to recondition this saw, and or is it worth fooling with. The saw was given to me a few years ago by an old landlord so it isn't something I cant part with.

In the last picture you can see the top needs some attention. What should I do to recondition this saw, and or is it worth fooling with. The saw was given to me a few years ago by an old landlord so it isn't something I cant part with.