Tafflad

Chief Petty Officer

- Joined

- Oct 23, 2007

- Messages

- 544

Volvo 4.3 280hp (2020)

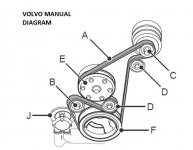

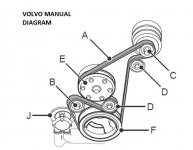

Went to fit serpentine belt, had not taken phot of it prior to removal for winterizing ….. as I knew it was displayed in the manual.

Unfortunately what is in the manual does not match the engine …

If you look at manual diagram it has an idler pulley D The 2nd

The 2nd

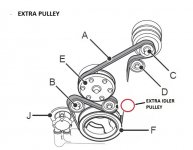

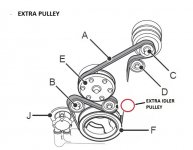

Whereas in actuality it has 2 idler pulleys – the extra one is not shown in Volvo maintenance book diagrams, diagram shows the position of extra idler pulley in RED

My guess is Volvo decided the longest belt run … between C+D to F was too long and added another idler to prevent belt flapping.

In the picture I have shown how I fitted belt …. – makes sense to me.

Belt tensions OK, and it does not impact the direction of rotation of any pulleys.

Anybody any comments ?

Went to fit serpentine belt, had not taken phot of it prior to removal for winterizing ….. as I knew it was displayed in the manual.

Unfortunately what is in the manual does not match the engine …

If you look at manual diagram it has an idler pulley D

The 2nd

The 2ndWhereas in actuality it has 2 idler pulleys – the extra one is not shown in Volvo maintenance book diagrams, diagram shows the position of extra idler pulley in RED

My guess is Volvo decided the longest belt run … between C+D to F was too long and added another idler to prevent belt flapping.

In the picture I have shown how I fitted belt …. – makes sense to me.

Belt tensions OK, and it does not impact the direction of rotation of any pulleys.

Anybody any comments ?