Texasmark

Supreme Mariner

- Joined

- Dec 20, 2005

- Messages

- 14,896

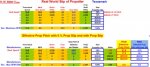

Props shown. Speed went from 50 @ 5700 with the 24 XP down to 40 with the 21P @ 5800 and 47.5 with the 21P at 6600. So let's extrapolate the 47.5 at 6600 up to 50 which would academically relate to 6600/47.5/50 = 6947 rpm. So I have a 3" pitch delta and a 10 mph speed change at roughly the same rpms. If I up the rpms to 6947 to get the speed near the 50 mph I could extrapolate to get the 6600 on up to the 50 number but the point is I changed pitch 3 inches x the 200 rpms per inch (recommended) numbers and they don't fit.

So assuming I had the 21 to start with and wanted to drop my rpms using the 50 mph speed number I would be working with 50/47.5 x 6600 =6947 rpms calculated. So for a given speed the pitch change was 3" and the rpm change was 6947/5700 = 1247.

So I theoretically have a 1247 rpm change for a 3" pitch change. Using the subscribed number of 150 to 200 rpm per inch (using the big number of 200) for a 3" pitch change would be 600 rpms. But mine changed 1247.

So, in short nothing is cast in concrete and rule of thumb is just a SWAG! You don't know a thing until you run it. Everything else is just that.....SWAGs and buyer beware. Besides you are dealing with A to Z in boats, weight, engines, props, hull efficiency, engine sizes, attitudes of the engine and hull, water and weather conditions, altitude differences, salt vs fresh water, currents vs no currents, state of repair and on and on.

So when you open a thread and say "I need a prop for xyz" here's a sampling of how complicated an answer can be,.

Hope this helps someone.

Mark

So assuming I had the 21 to start with and wanted to drop my rpms using the 50 mph speed number I would be working with 50/47.5 x 6600 =6947 rpms calculated. So for a given speed the pitch change was 3" and the rpm change was 6947/5700 = 1247.

So I theoretically have a 1247 rpm change for a 3" pitch change. Using the subscribed number of 150 to 200 rpm per inch (using the big number of 200) for a 3" pitch change would be 600 rpms. But mine changed 1247.

So, in short nothing is cast in concrete and rule of thumb is just a SWAG! You don't know a thing until you run it. Everything else is just that.....SWAGs and buyer beware. Besides you are dealing with A to Z in boats, weight, engines, props, hull efficiency, engine sizes, attitudes of the engine and hull, water and weather conditions, altitude differences, salt vs fresh water, currents vs no currents, state of repair and on and on.

So when you open a thread and say "I need a prop for xyz" here's a sampling of how complicated an answer can be,.

Hope this helps someone.

Mark

Attachments

Last edited: