GSPLures

Chief Petty Officer

- Joined

- Sep 3, 2019

- Messages

- 564

How are you all doing today,

I have a 73' 140 mercruiser with mc-1 drive and the black prestolite pump.

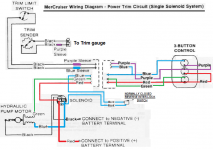

I have the tilt/trim hooked up working and not leaking finally. I changed all the wire ends on the 3 button panel and pump side one at a time so I do not believe its a circuit issue. Although the boat was in horrible condition before I started restoring it so who knows if its right (I did refer to the schematics and didnt see anything wrong)

The hydraulic lines coming in from the transom are hooked up right I am assuming because with the lengths of the hoses they cannot go the other way.

Not sure if I have the hoses hooked up right on the outside though. (See picture, I am hoping its as easy as switching the lines)

Bottom button: trim goes up(also to trailering position)

Middle button: nothing

Top button: nothing

Middle/top together: drive goes down

I know there are some other issues as well because the buttons are not doing what it should. Im ok with having to hit 2 buttons at the same time but would like to at least have the top make it raise and the bottom make it lower.

I have a 73' 140 mercruiser with mc-1 drive and the black prestolite pump.

I have the tilt/trim hooked up working and not leaking finally. I changed all the wire ends on the 3 button panel and pump side one at a time so I do not believe its a circuit issue. Although the boat was in horrible condition before I started restoring it so who knows if its right (I did refer to the schematics and didnt see anything wrong)

The hydraulic lines coming in from the transom are hooked up right I am assuming because with the lengths of the hoses they cannot go the other way.

Not sure if I have the hoses hooked up right on the outside though. (See picture, I am hoping its as easy as switching the lines)

Bottom button: trim goes up(also to trailering position)

Middle button: nothing

Top button: nothing

Middle/top together: drive goes down

I know there are some other issues as well because the buttons are not doing what it should. Im ok with having to hit 2 buttons at the same time but would like to at least have the top make it raise and the bottom make it lower.