stickermandan

Cadet

- Joined

- Jan 16, 2014

- Messages

- 17

Re: Transom repair

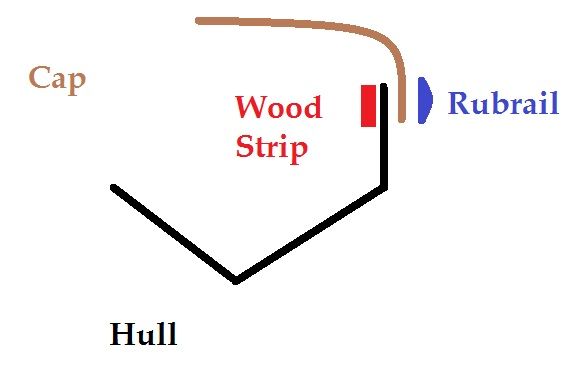

oldboat1, that is exactly what I had come up with over the weekend for installing the transom wood back in the boat. the outside fiberglass is fine around the motor holes and the drain plugs. I figured cutting the correct arch and angle out of a 2x8 on its side, use the convex cut off on the inside and the concave piece on the outside. Then use carraige bolts or all tread and nuts to sandwich the new perfectly formed transom plys with kerfing cut into the plys to bend a little easier, thru the existing engine holes I would think there would be adaquate pressure across. To keep pressure at the bottom I think i could do the same thing but use the drain plug hole. I'd have to get a closer look at that I guess. Across the top I will just use some wood clamps I think should be sufficient. After the wood is laminated correctly in place, the plan was to reglass the inside, tab it all the way around and use a piece of 1708 over the top to seal it off and give a bit of extra strenght. Does this sound correct?

After the transom is finish, I figured I'd take the advice from the other threads I've seen and over drill the motor and water drain holes then fill will PB and redrill them the correct size. I relize I will need to set the drain plug with more PB to seal correctly.

oldboat1, that is exactly what I had come up with over the weekend for installing the transom wood back in the boat. the outside fiberglass is fine around the motor holes and the drain plugs. I figured cutting the correct arch and angle out of a 2x8 on its side, use the convex cut off on the inside and the concave piece on the outside. Then use carraige bolts or all tread and nuts to sandwich the new perfectly formed transom plys with kerfing cut into the plys to bend a little easier, thru the existing engine holes I would think there would be adaquate pressure across. To keep pressure at the bottom I think i could do the same thing but use the drain plug hole. I'd have to get a closer look at that I guess. Across the top I will just use some wood clamps I think should be sufficient. After the wood is laminated correctly in place, the plan was to reglass the inside, tab it all the way around and use a piece of 1708 over the top to seal it off and give a bit of extra strenght. Does this sound correct?

After the transom is finish, I figured I'd take the advice from the other threads I've seen and over drill the motor and water drain holes then fill will PB and redrill them the correct size. I relize I will need to set the drain plug with more PB to seal correctly.