Hydra-sport_Road-kill

Petty Officer 2nd Class

- Joined

- Jun 15, 2011

- Messages

- 123

I'd like to ask for advice from the many learned fiberglass sages on how to approach repairing the skin of a transom in this poor condition (see pics). The outer skin has so many holes and is also quite thin. Along with mounting holes there are some stress tears where a motor was mounted at some previous time. This seems to have been repaired by slathering 5200 in the seams and the application of an 1/8 inch thick 14" x 17" steel plate (now removed and the genesis of the big rectangular shadow/stain). I think from reading numerous threads that you folks do your best work with ?Here's what I got now what do I do about it?? scenarios that include lots of pics.

If there is any need for more pics just let me know.

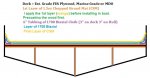

I've done my reading and research on various repairs to the hull here on iBoats and the library and I?ve read the hull extension thread front back and sideways but I?d like to get any particular cautions or techniques before I dive in. The rest of the transom rebuild would seem to follow this procedure, am I right?

If there is any need for more pics just let me know.

I've done my reading and research on various repairs to the hull here on iBoats and the library and I?ve read the hull extension thread front back and sideways but I?d like to get any particular cautions or techniques before I dive in. The rest of the transom rebuild would seem to follow this procedure, am I right?