Re: Tri hull restoration project

sorry ...my puter was sick for a couple of days.

ok.....back to the poly epoxy thing.....use one or the other.

i suggest poly.....it is plenty strong enough to do what you need.

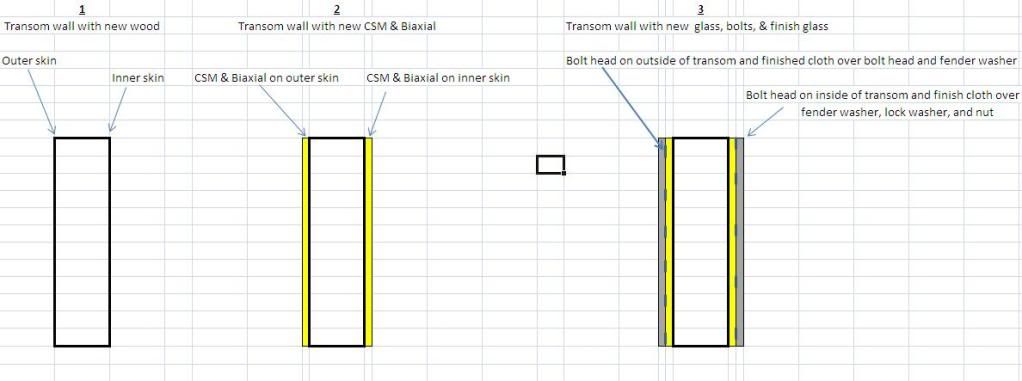

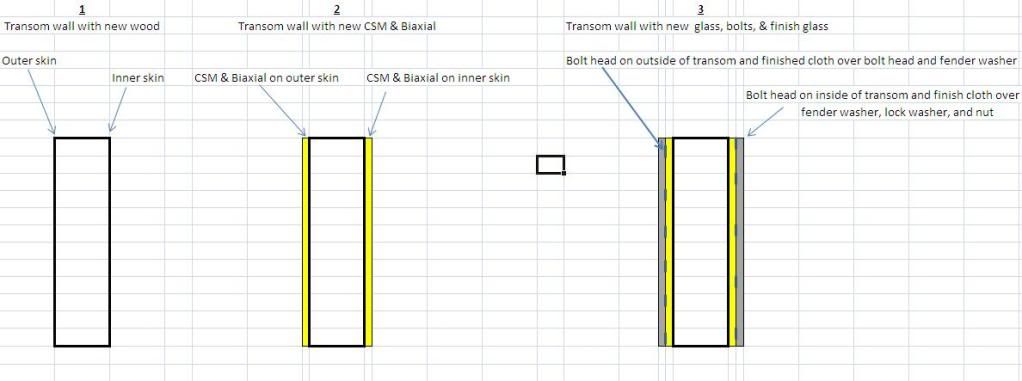

first off....grind off the gellcoat on the entire transom...make sure its as smooth as you can. fill the gap between the cut with structural filler peanut butter.....the recipe is in my sig ...use the index. (oops super dooper structural peanut butter)

as well ...grind off the 6 inches of gellcoat all around the transom....on the sides and on the hull.

then clean with acetone...use 2 layers of csm.....i 1708....1 csm....1 1708....1 csm...and a 6 oz finishing veil.

make sure this wraps around to the out dies of the side and under the boat.

(yep....you really screwed the pooch when you cut the transom off bud

that is why we say before you start...read read read )

you are worried about the bump between the sides and bottom and the transition to the new glass.

this is going to require a lot of fairing. possibly a few more layers of glass to go longer up the hull and sides.

after its back to flat.....(dont leave a hump on the plaining surface) then you can re gellcoat this area.

for the inner hull.......after the transom is glass in from the out side.......then you are back at squair one...

grind off the inner glass.....and use the same layup schedule for the inside......wrap the glass around the inside edges...

then you can do your stringers and deck.