Key west Tom

Seaman Apprentice

- Joined

- Jun 5, 2005

- Messages

- 32

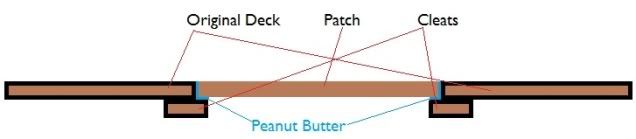

I need to replace a leaking fuel tank under the floor of my 1996 Key West boat. This floor does not have a removable cover or hatch so I will have to cut the floor to get to the tank.On the floor there is a "cut line" that is molded into the floor, this looks like this is where I need to cut. question is, when I put it back together, how do I get the floor to look right? I don't want to paint or put carpet down to cover the seam. I was thinking about useing epoxy to make a ledge around the opening and setting the cut out floor back down then more epoxy trickled into the cut line to fill the gap. Can I tint the epoxy to match the gelcoat of the floor?

Any other ideas? how do the pros do it?

Any other ideas? how do the pros do it?