Hate to say it, but that's probably the wrong motor for that heavy boat. Merc 1500's like light-loading and fast hulls. They are not ported for low-end torque.

You'll need to make the engine wind-out to get it to push that much weight. More important than just guessing what pitch will work, you need to know what the Wide-Open-Throttle rpm is, when just the driver is in the boat. Then you can figure out where to go on prop size. A 1500 Merc Inline needs to be running at least 5500 rpm WOT to be propped correctly. Most of them will be quite happy to rev to 6000, BTW!

IMHO a 17" pitch probably won't be low enough. I believe there is a 16" pitch available in an aftermarket prop, this might be better than a 15" pitch but you never know.

You won't be able to find a 14" diameter prop for an inline, they don't make 'em unless it's custom-made and custom-fit; the gearcase won't typically accommodate that large of diameter. Inlines do not "like" large-dia props anyway; you'll want a smaller dia (like 13" or 13-1/4", for example) for better acceleration.

BTW that link to prop selection does indicate at the top of the page that the props listed are for Merc outboards, so I can only assume that they'd fit. You'd just have to carefully check application charts to be sure.

Another trick that can get a heavy hull on plane is to drill ventilation holes in the prop. The exhaust flowing over the prop upon takeoff provides a controlled "ventilation" of the prop and lets the engine speed up faster into its rated rpm. Beware, though, you don't want to go any larger than 5/16" or the prop will ventilate so much that it'll never hook up. 1/4" holes or even 3/16" are better to start out with.

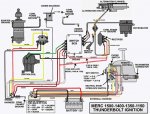

Note that a lot of aftermarket hi-performance props come with holes or slots, so this is a proven technique. See the diagram posted below.

Anyway, figure out your WOT rpm and we'll be able to more better help you determine the correct prop pitch for your motor/boat combination.......ed