Re: Using Seacast for the first time!

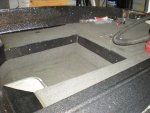

These pictures are showing how my Glassport transom looked like at the time of the pour.The first thing that I did was determine how much wood was really in the transom. next after figuring out where I should make my cuts,I used my air cutting tool and carefully sectioned out the top portion of the transom and carefully lifted off the lid.

Then the fun part began!

I spent the next 7-8 hrs digging the old mush out. That proved to be a difficult job as there is only about 1 1/2 inches to work around inside there with your tools.--I had to use several different long drill bits and drill spades to pulverize the wood enough that it will come out!--Then I used a shop vac and my air compressor to blow out the rest of the wood pieces.

After all of that was done,I was ready for the prep work.

I replaced the drain tubes in the splash well and remounted everything that went into the transom, like all of the engine mount bolts,fish finder and the airator pump line. I did this because it was easier now to install all of it at this point than having to drill things out later--There is no need for any greasing of these parts before the pour, because the seacast will not stick to them!

Next follow all the directions in mixing the Seacast, it is very important to do it how the directions say!

Have some acetone around to clean spills and drips (it will get real messy)

Have some help around in mixing and pouring process, it really helps! In this case a friend of mine came by and gave me a hand in mixing and pouring--I made up plexi glass frame work around the opening to act like a funnel to help with the pour--It worked ok.

As it was poured in, I used a rubber mallet and tapped on the outside rear of the transom to get the air bubbles out--It got real messy at this point,dont get flustered, just get it in the transom and then clean your spills up!

Dont worry about time, there will be plenty of time to fill up your area before it starts to set (about 45 min)

The catallist kicks in at some point and the transom gets really warm (really neat !)

Clean up your drips and spills with acetone and trowel the edge flat.

Hook up a heat lamp but not to close and let it harden.

Grind and sand the Seacast flat,remount the lid, fill, prep, repaint, remount trim---then you are finished!

My boat came out very nice,I was impressed how easy it was in this case, and how strong it is now!--I think that it is stronger now than when it was built new!

If anyone wants any input or has questions about Seacast,don't hesitate to email me!