Hey all. I'm replacing the PDS bearings/snap rings and seals on a 290-DP. For some reason, the rear bearing failed within 3 years and i'm thinking the alignment may have been off. Timken bearings (purchased through iBoats) were used and the PDS was pumped with grease religiously.

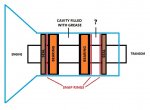

1 - Can someone please tell me what the approx 1" space is for - see below from my crude artwork - that has the "?" between the 2 large snap rings, aft side? Is it to hold some grease behind the aft bearing before it gets pushed out when doing a "grease replacement" when pumping the zerk during maintenance? If i have this drawing incorrect, please let me know. I am aware there is another smaller snap ring that goes behind aft bearing, just couldn't draw it in nicely without confusion and also that both seals face the same way so that grease can escape through the aft seal during maintenance.

2 - From the many posts I've read, please let me know if i have the engine/flywheel cover/transom shield alignment procedure correct or missing something. Bolt the flywheel cover to the engine, slide this unit back lining up the 6 bolts that go through the transom into the flywheel cover, lower unit to rest on the motor mounts, tighten the 6 bolts evenly to 35ft lbs, adjust unit left/right/up/down to achieve no more than a 2mm difference between the 3 alignment bosses (located @ 3, 9, 12 o'clock) between the transom shield and flywheel cover, install and tighten motor mount lag bolts, recheck alignment boss spaces, re-adjust motor mounts if necessary.

Thanks in advance for any and all help,

Jersey

1 - Can someone please tell me what the approx 1" space is for - see below from my crude artwork - that has the "?" between the 2 large snap rings, aft side? Is it to hold some grease behind the aft bearing before it gets pushed out when doing a "grease replacement" when pumping the zerk during maintenance? If i have this drawing incorrect, please let me know. I am aware there is another smaller snap ring that goes behind aft bearing, just couldn't draw it in nicely without confusion and also that both seals face the same way so that grease can escape through the aft seal during maintenance.

2 - From the many posts I've read, please let me know if i have the engine/flywheel cover/transom shield alignment procedure correct or missing something. Bolt the flywheel cover to the engine, slide this unit back lining up the 6 bolts that go through the transom into the flywheel cover, lower unit to rest on the motor mounts, tighten the 6 bolts evenly to 35ft lbs, adjust unit left/right/up/down to achieve no more than a 2mm difference between the 3 alignment bosses (located @ 3, 9, 12 o'clock) between the transom shield and flywheel cover, install and tighten motor mount lag bolts, recheck alignment boss spaces, re-adjust motor mounts if necessary.

Thanks in advance for any and all help,

Jersey