Today's update.

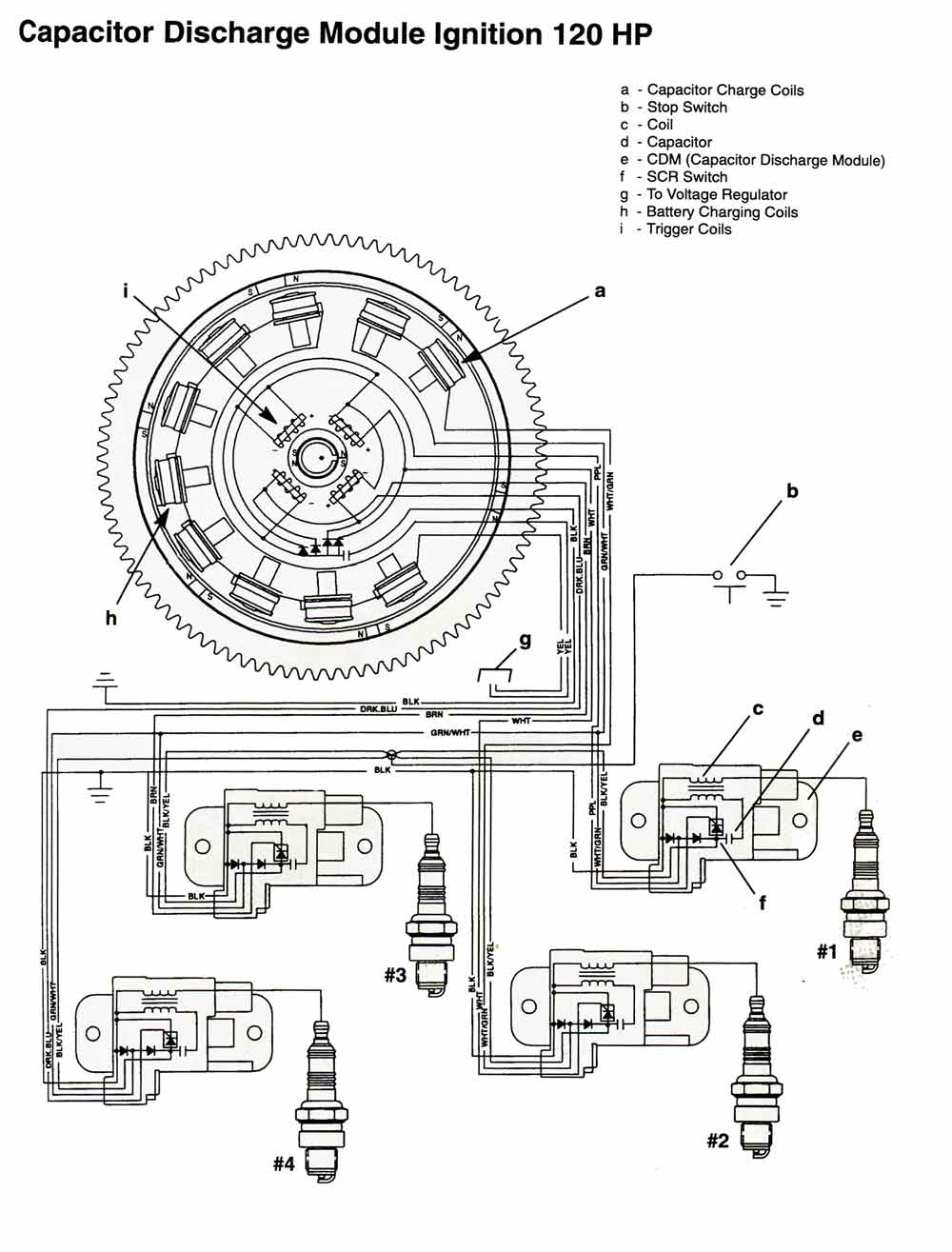

OK yesterday I went out in the morning to test start the Frankenforce ignition and no start, no spark. I took the adapter out and the ignition did spark, but of course the timing was off. I fiddled, resoldered connections etc and later it would start every time.

This morning I went out first thing and the same ting, but I decided that instead of removing the adapter I would try jumping the white / black common wire to ground and bypass that part of the circuit. Spark and cranked right up, but of course the timing was off, but also of course the timing came right back after I unclipped the jumper.

I am thinking that perhaps fine tuning the circuit values might get that initial pulse over the 0.6 DVC to fire the CDM modules or perhaps add a reed relay that in turned on by the starter to by pass that part of the circuit for starting. I hate to add more complexity, but if it works ....

Thinking more about the circuit design and how to work this problem.

Undoubtedly the early push - pull coils have lower voltage output than the later single ended CDM trigger coils.

At idle the capacitor charges to around -8 DVC and the wires going to the CDM modules is around - 5 VDC.

Once the engine is running the coild are generating enough voltage to fire the CDM, but not quite at cranking speed, I assume.

One almost wishes for a system like the old battery ignition that would generate a spark no matter the speed.

It looks like I need to get the Oscilloscope out like I have threatened to actually see what the levels are.