Thanks WoodonGlass, I will do like that.

I will also continue with the story and post the last pics of it. I must apologize for leaving that post alone. As the ending of the restoration came closer, I felt more nervous about finishing it faster and lazy about taking pics.

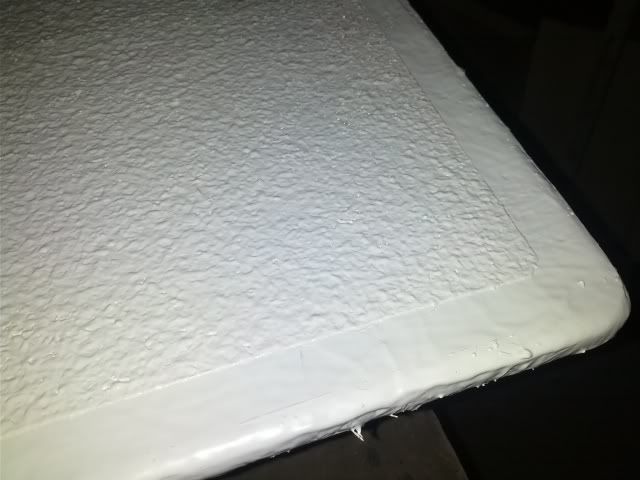

Basically I re-done all the no-slip surfaces using a roller while teh gelcoat cured. And then sanded it until the surface was soft and nice to bare feet.

There's a sample before sanding.

That's a picture of the contro, panel restoration before painting the interiors:

Then I painted with poliurethane all the newly built surfaces. That's a picture of how the bow ended. I'm very proud of it.

The edges of the seats don't deflect a bit. I can stand still on those edges without it deflecting.

This is a detail of how I modified the consoles feets to be more modern. Those ugly tabs that you can see on the interior are to bolt a covering panel, so the space under the consoles become two lockers.

I initially thought about making a custom doors on the sides, but the pvc doors on ebay are so available that I will order a pair of them and bolt in place. I was having hard times moulding the recesses for the doors.

From that picture, I finished the floor.... and ended the rest of the boat (I promise I'll take some pics)

When I made the non-slip surface on the bow, the excess paint on the floor made the gelcoat not adhere, so the edges are lifted. I'm currently repairing it.

I also polished the liner around the boat and it seems now like stainless steel. Painted the rubber black.

So by now It only lacks making all the interiors, cushions and seats, but as the heat already came and we were so tired we mounted the old ones and went to do a testing session at the river.

It was amazing! We all where so excited that forgot to take a camera or even a phone. We all where in swimsuits before leaving the car.

The trailer was incredible for launches. It is fully articulated.

I expected the engine needing adjusting and everything to fail but I was wrong. It started at the first stroke and came into gear easily.

The only problems where: I didn't forgot to wire the switch interrupt, so being my first time at command was very scary when I realized that the thing didn't want to stop while approaching the dock (Doh!) i killed the engine instead.

As I also had to repair the accelerator cable (seized, so I replace the cover) It was a little offset. So I adjusted.

And I found an hydraulic trim leak at the trim motor hose. I fixed later with a new temporary clamp.

So we made some rides with it. I'm not experienced with boats, but my wife has plenty, as his family always had all kinds of boats. she said that she was very impressed of the ease of the boat to climb the hole and the small bit of time it takes.

I noticed that the boat was cruising so level, and I expected some more rear dive, perhaps by the weight reduction, but she told me that she was absolutely perfect. That she never ride a boat that planed that well. It's true that I could barely notice the water going under it and it seemed like flying.

She told me that it was a very very fast boat. Well, it's right. I didn't pass 70% of gas and I don't have a working speedo but I was so scared at the river turnings.

So the conslusion we made about replacing all that wood with composites it's that the boats manners turns more into something like a jet bombardier. That was the feeling I had, and what I wanted.

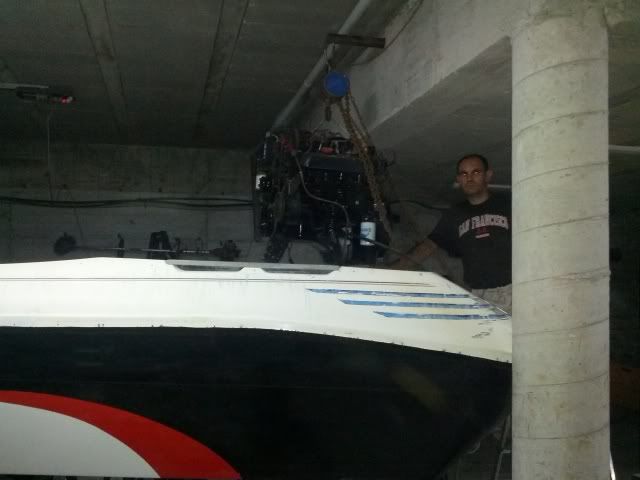

Now.... I'm making some engine cover so we can invite some family.

And we're changing the boats name! We decided for Arcadia. From "The happy Arcadia" country myth.