nola mike

Vice Admiral

- Joined

- Apr 22, 2009

- Messages

- 5,786

Ok, finally made it back. Compression was initially a little low. After some cranking, I ended up with 150-160 psi in all six.

And then off with its head(s)!

Some carbon in there, but the cylinders looked good. Walls very smooth. Double checked the '89, it does have a roller cam btw. The '01 has a roller cam, and the rocker arms have a roller in the fulcrum as well, and appear to be the non-adjustable type. New engine was a manual, so I have a flywheel. The cover from the old one looks like it fits. Got the glass arriving tuesday. I'll clean and sand the bilge in the meantime. Aside from the HG and core plugs, what do I want to replace while I have the engine out? Gaskets? oil pump? Mounts?

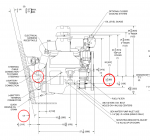

This one I'm just proud of my organization

And then off with its head(s)!

Some carbon in there, but the cylinders looked good. Walls very smooth. Double checked the '89, it does have a roller cam btw. The '01 has a roller cam, and the rocker arms have a roller in the fulcrum as well, and appear to be the non-adjustable type. New engine was a manual, so I have a flywheel. The cover from the old one looks like it fits. Got the glass arriving tuesday. I'll clean and sand the bilge in the meantime. Aside from the HG and core plugs, what do I want to replace while I have the engine out? Gaskets? oil pump? Mounts?

This one I'm just proud of my organization