bollerwagon

Petty Officer 2nd Class

- Joined

- Oct 15, 2020

- Messages

- 102

Reassembling my Volvo Penta AQ271C after honing, the piston rings I purchased (Sealed Power Performance Piston Ring Sets E251K) don´t seem to fit. The piston is a GM piston p/n 10046106, I assume there are the original ones.

With this piston the oil scraper rings were too wide, the piston ring was not fitting into the groove completely and the piston could not be inserted into the cylinder.

Since on of the piston showed some wear, we decided to take new pistons. There the oil scraper rigs fitted fine.

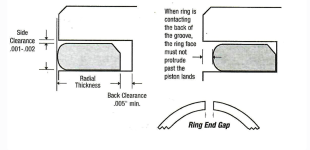

But then we noticed, that the compression ring #2 would not fit into piston. The rings (#1 and #2) have a thickness of 1.89mm as they should have according to the manual. But the groove of the pistons was different. While #1 was fine, #2 sits way too tight. Clearance should be 0.03-0.11mm but on #2 it was basically zero. Weirdly same phenomenon shows on the old pistons.

So I am confused now and don´t know what to do.

With this piston the oil scraper rings were too wide, the piston ring was not fitting into the groove completely and the piston could not be inserted into the cylinder.

Since on of the piston showed some wear, we decided to take new pistons. There the oil scraper rigs fitted fine.

But then we noticed, that the compression ring #2 would not fit into piston. The rings (#1 and #2) have a thickness of 1.89mm as they should have according to the manual. But the groove of the pistons was different. While #1 was fine, #2 sits way too tight. Clearance should be 0.03-0.11mm but on #2 it was basically zero. Weirdly same phenomenon shows on the old pistons.

So I am confused now and don´t know what to do.