I thought the same thing Ted, have the risers ever been off? If not it could be something like that. Is the exhaust on these newer Mercs cast iron or aluminum? I never checked my brothers 4.5 when he had one. He had one mild overheat (simple solution rod out the water intakes) but that was enough for him he traded it on a similar boat with a 4 stroke outboard…I hope it’s cooler where you are than it is here! Way too hot to be hanging upside down in the bilge!

Hi

@Lou C -

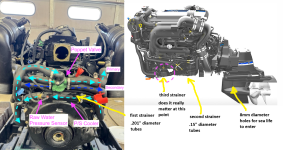

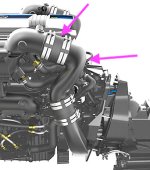

The exhaust is steel, both manifold and risers. AFAIK - The exhaust has never been inspected or replaced. The boat is in its 10th season, so not a surprise that it needs some love.

Out in the bay, I was getting a water temp of 78˚F . . . in the harbor it was a little less. We usually peak-out in water temp in early August. I think most of our 'heat' comes from the gulf stream.

The coolant side looks fine on both engines . . . full and no evidence of coolant loss.

The manifold/riser gaskets show no signs of seepage or rust. . . speaking of gaskets, I just checked the price of the new-style gaskets (full block-off/closed cooling) (8M2004606) prices ranging from $165 - $200 per gasket

. So, even to inspect the risers, the parts would be $800 ish