- Joined

- May 16, 2009

- Messages

- 9,212

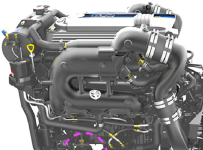

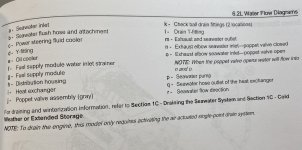

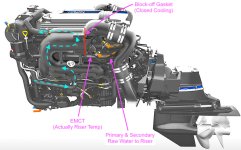

If you haven't seen it yet, i found your service manual and it shows the water flow and suggests the strainer (F) I mentioned earlier is for the fuel module... The link will start at the beginning that covers both standard and closed cooling but you got to scroll through them to see the differences and the notes on the next page that may and may not cover the previous water flow guide shown of each design differences.

www.manualslib.com

www.manualslib.com

a -

Seawater inlet

b -

Seawater pump

c -

Power steering fluid cooler

d -

Y‑fitting

e -

Drain fitting

f -

Fuel supply module water inlet strainer

g -

Fuel supply module

h -

Distribution housing

i -

Drain fitting

j -

Y‑fitting

k -

Water circulating pump

l -

To engine block (from water circulating pump)

NOTE: When the poppet valve opens water will flow into (r and s)

90-8M0099748 eng DECEMBER 2015

m -

To crossover (from engine block)

n -

Crossover with 60° C (140° F) thermostat

o -

Exhaust manifold seawater inlet and drain

p -

Exhaust and seawater outlet

q -

Poppet valve assembly (green)

r -

Exhaust elbow seawater inlet (poppet valve closed)

s -

Exhaust manifold seawater inlet (poppet valve open)

t -

Starboard exhaust manifold drain hose

u -

Port exhaust manifold drain hose

v -

Starboard engine block drain hose

w -

Port engine block drain hose

x -

Oil cooler

Mercury MerCruiser Service Manual (Page 449 of 566) | ManualsLib

a -

Seawater inlet

b -

Seawater pump

c -

Power steering fluid cooler

d -

Y‑fitting

e -

Drain fitting

f -

Fuel supply module water inlet strainer

g -

Fuel supply module

h -

Distribution housing

i -

Drain fitting

j -

Y‑fitting

k -

Water circulating pump

l -

To engine block (from water circulating pump)

NOTE: When the poppet valve opens water will flow into (r and s)

90-8M0099748 eng DECEMBER 2015

m -

To crossover (from engine block)

n -

Crossover with 60° C (140° F) thermostat

o -

Exhaust manifold seawater inlet and drain

p -

Exhaust and seawater outlet

q -

Poppet valve assembly (green)

r -

Exhaust elbow seawater inlet (poppet valve closed)

s -

Exhaust manifold seawater inlet (poppet valve open)

t -

Starboard exhaust manifold drain hose

u -

Port exhaust manifold drain hose

v -

Starboard engine block drain hose

w -

Port engine block drain hose

x -

Oil cooler