Squirrel42

Petty Officer 2nd Class

- Joined

- Mar 23, 2016

- Messages

- 109

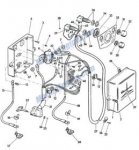

This is my first 50s engine and I'm a little lost.. I found this old 1957 that needs some work, I'm having a hard time finding the correct parts. I find more information about the Javelins by Johnson and the Big twins by Evinrude. Do these engines share any parts with each other, at least around the same year?

Any good pages like Leroy's rambles that might be good for informative information on rebuilds for this engine.

The engine seems to be in alright shape, not much rust. pretty clean compared to some finds i have seen on the site.

Looking forward to throwing this on a 1956 Alumacraft FD I'm currently redoing the transom on.

Any help is appreciated, really looking for a good wright up on this engine.

Any good pages like Leroy's rambles that might be good for informative information on rebuilds for this engine.

The engine seems to be in alright shape, not much rust. pretty clean compared to some finds i have seen on the site.

Looking forward to throwing this on a 1956 Alumacraft FD I'm currently redoing the transom on.

Any help is appreciated, really looking for a good wright up on this engine.