Re: 1967 IMP Aztec -- Thoughts and suggestions for Rebuild maybe repower

Re: 1967 IMP Aztec -- Thoughts and suggestions for Rebuild maybe repower

thanks for the pm with this link.....there is so much going on in the forum that i have a hard time keeping up with all the progress.

gaps like that are common......while some will be taken up by the transom being bolted to the skin...some wont...

at this time.....you are only worried about the actual interface of the transom/skin on the aft of the boat......do not be concerened with the edges...just the flat face to face bonding....no gaps allowed.

the good thing is that you can identify the areas....

do a dry bolt up to the skin......thats right...bolt your transom on dry....then look from the outside and see if you are warping your skin. if you are....relax the bolts till there is no warpage....everything is flat and straight.

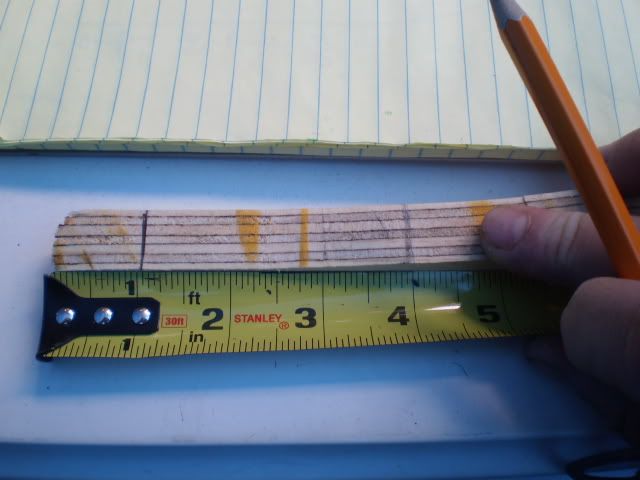

now...re measure the gaps......if the gap is more than a 1/4 inch......try to measure the depth as best you can. and mark on the inner skin what areas they are. and how thick.

a extra layer of csm or 1708 right across that area will eat those gaps up no problem....

so....at the top of the transom.....you might have an area where the skin pulls away from the wood.....that is 4 ins deep getting worse near the top.

as discussed earlier in a standard transom instlation. you add csm to the skin as well as the transom...this glass is wet on wet.

ON THE SKIN SIDE....add another layer of csm in the void areas...this strip might be 4 inches deep running the width of the transom......then possibly a strip of 1708 at 3 ins down from the top and across the width...with another layer of csm at one inch.

basically....fill the gaps with fiberglass.

a few things to watch for..... use less mekp for thicker glass applications......for instance....with this layup you have 5 layers of glass between the wood and skin...so you will want to catylize colder....try 1.7 percent.

the other thing....is wait a minit or two after you glass the skin and transom till the install....not 5 mins...just a minit or two.....the glass will want to slide with more layers...so take extra care when installing the transom....you cant have the glass bunch up causing an air void or un even surface between the wood and the skin.

this is where your dry fitting practice comes in.....you have to be profecent with fitting it and know you can do it with out moving the glass on the wood or the skin....the glass will be wet...the styrene will break down the csm...and it will want to move easily.....getting the transom in with out twisting on it is crutial.

....now....the gaps around the edge are filled with peanut butter......after the transom is bolted in....and curing......take a putty knife and push peanut butter as far into the gaps as you can.....you want to fill the gaps totally (or as best you can) this will take a lot of peanut butter...so work in small batches or the stuff will cure in the bucket on you. do not add peanut butter to the bottom first and set the transom on it.....add the pb after.

Thanks alot.

so would it be better, once i have dry fitted the transom as described, to build up the area on the SKIN SIDE with the layer of CSM, then once tacked, fit the transom again and check, then if needed, do the layer of either 1708 or CSM, then fit again, or just try and measure as close as possible with the dry fit and then do the build up, then the CSM on the transom and once both tack mate them together?

Once i have the transom in place and bolted, i should wait about 4 hours before removing the clamps? then i can start the stringer installs? I kind of like the idea of a faster set time using the PB for filleting and not using the PL at all for it so I do not have to wait the 24 hours before moving onto the stringer install.

once the clamps are off i can start the PB install around the transom or can i do it at the same time?