3rdMarDiv

Petty Officer 3rd Class

- Joined

- May 27, 2013

- Messages

- 84

Re: 1972 20HP Chrysler Fuel pressure problems

I have a 202HG and two 203HD model 1972 20hp Chryslers. The 3rd motor a 203HD is being worked on now. Each one has had sucking air problems. They all ran fine in the barrell but on the lake at WOT bogged, accelerated then decellerated, etc. With time and patience two are running like swiss watches. I am still fooling around with 3rd motor, 203HD.

Please post any measures you try as they may not have worked for you, but might for someone else.

A few things I can add here are that these motors were built like tanks, but some of the smallest things can cause poor operating conditions. Something a simple as the O-Ring at the mortor connection clamp will cause a sucking air condition.

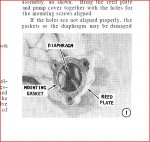

Many diagrams of the fuel pump for this motor you will see on the NET are printed wrong. They will show the pump diaphram as next to the powerhead and then 2 gaskets. It's gasket, diaphram, gasket like a sandwitch.

I prefer to sit the fuel bowl down and place a small flat screwdriver head against the tab, depressing the tab until the float pin is seated. The float should be level with the bowl casing at that point. There is a spring attached to the pin that may cause the float not to fully raise when turned upside down. That spring needs to be connected to the float tab also.

For best results sit the bowl down and fill with mineral spirits and see where the bowl is at at full close.

Age is problem and there is gasket between the powerhead and upper motor leg that can crack and leak air both ways. With the engine running in the barrell spray some choke cleaner around the connection area and if the engine speeds up then you have a bad gasket. It's an easy repair.

Of course, the points and gap should be cleaned and checked. New plugs gapped properly, etc. Carb cleaned with new gaskets. Check float pin for wear, etc.

Check for spark buy grounding plugs and hand rotating flywheel.

With engine running put a VOM around the plug wires to check for like output.

Hers some pics of a pump I put back on a 202HG. I also put a thin coat of Permatex Permashield Blue (Fuel Resistant) on metal to gasket locations. This is not the Ultra Blue Gasket Maker. I'll be watching this thread and thanks to everyone for any assistance...:joyous:

And, there are no springs only thin metal reeds.

Oh, and I'm not a mechanic so if I have said something wrong go easy on me...I consider myself an advance hobbiest... eace:

eace:

I have a 202HG and two 203HD model 1972 20hp Chryslers. The 3rd motor a 203HD is being worked on now. Each one has had sucking air problems. They all ran fine in the barrell but on the lake at WOT bogged, accelerated then decellerated, etc. With time and patience two are running like swiss watches. I am still fooling around with 3rd motor, 203HD.

Please post any measures you try as they may not have worked for you, but might for someone else.

A few things I can add here are that these motors were built like tanks, but some of the smallest things can cause poor operating conditions. Something a simple as the O-Ring at the mortor connection clamp will cause a sucking air condition.

Many diagrams of the fuel pump for this motor you will see on the NET are printed wrong. They will show the pump diaphram as next to the powerhead and then 2 gaskets. It's gasket, diaphram, gasket like a sandwitch.

I prefer to sit the fuel bowl down and place a small flat screwdriver head against the tab, depressing the tab until the float pin is seated. The float should be level with the bowl casing at that point. There is a spring attached to the pin that may cause the float not to fully raise when turned upside down. That spring needs to be connected to the float tab also.

For best results sit the bowl down and fill with mineral spirits and see where the bowl is at at full close.

Age is problem and there is gasket between the powerhead and upper motor leg that can crack and leak air both ways. With the engine running in the barrell spray some choke cleaner around the connection area and if the engine speeds up then you have a bad gasket. It's an easy repair.

Of course, the points and gap should be cleaned and checked. New plugs gapped properly, etc. Carb cleaned with new gaskets. Check float pin for wear, etc.

Check for spark buy grounding plugs and hand rotating flywheel.

With engine running put a VOM around the plug wires to check for like output.

Hers some pics of a pump I put back on a 202HG. I also put a thin coat of Permatex Permashield Blue (Fuel Resistant) on metal to gasket locations. This is not the Ultra Blue Gasket Maker. I'll be watching this thread and thanks to everyone for any assistance...:joyous:

And, there are no springs only thin metal reeds.

Oh, and I'm not a mechanic so if I have said something wrong go easy on me...I consider myself an advance hobbiest...