OK, this boat is a bit weird, maybe someone else can confirm or explain the Sea Ray Construction methods from the late 70s.

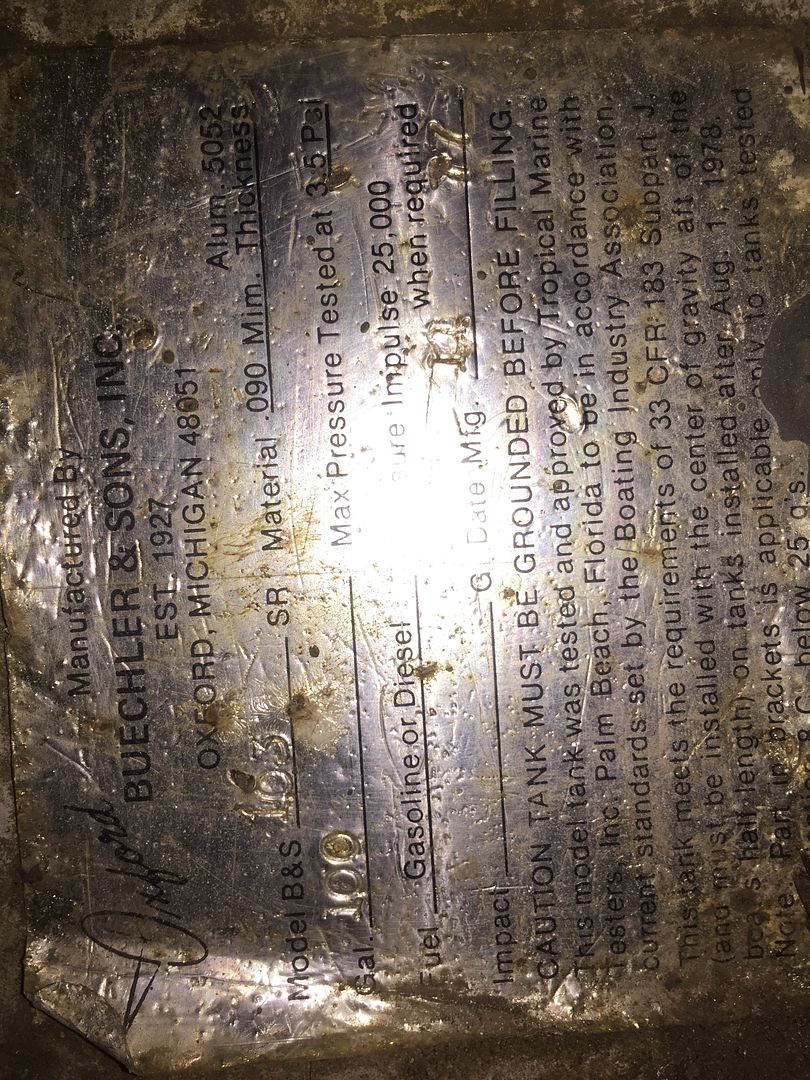

I got to digging in the boat more this weekend thinking I would dig the 100 gallon fuel tank out. I already cleaned off the top of it front to back, now at the rear there is the bulkhead between the tank and engine bay. The bulkhead immediately behind the tank is/was 3/4" ply with fiberglass on both sides. To either side of that bulk head is some really thin plywood, maybe 3/8" thick at most with fiberglass on both sides. I found a hole in the fuel tank on the rear about mid way down, rust/corrosion hole. The 3/4" thick piece of plywood was only rotted on the very port side edge, the rest of it was solid. The bulkheads on either side of the fuel tank are completely rotted inside the glass, just wet black mush in there.

Now here comes the weird part. What I thought were stringers on either side going from the transom to the engine bay front bulkhead don't really look like stringers. When I drilled into them a couple months ago, I noted water came out of almost every hole I drilled. What I didn't notice is there doesn't appear to be any fiberglass on the back side of those "Stringer" looking boards. It looks to be foam inside a box and the box was not fiberglassed on the inside, only the exterior. The dimensions appear to be the same on port and starboard sides, just a vertical board and horizontal board forming a flat surface for a block of foam on the starboard side and a plastic water tank on the port side to sit on top of. I removed those tanks and started cutting into the plywood. The top board does appear to be fiberglassed on both sides, but the vertical board does not. A screwdriver goes through the exterior fiberglass, through some mush, then into foam.

So what am I missing here? Does this boat not have structural stringers? Is the fiberglass thick enough to maintain hull rigidity alone? Or is it counting on these bulkheads of 3/8" plywood only fiberglassed on one side to handle things?

See pics:

Bulkhead behind fuel tank:

What happened after I used my grinder with cutoff wheel to cut horizontally across and try to remove that bulkhead. See the water draining?

Port side rot of bulkhead behind tank?

Starboard side rot of bulkhead behind tank?

bulkhead removed, you can see the back of the tank, but I need to go lower to cut it out and get the tank out. You can see the hole in the tank. Any suggestion on how to break the tank free? I?ve got to take some measurements before I cut anything else out like the engine mount pad.

Port side stringer/box uncut?water tank removed

Cutting into the top of the port side stringer box and peeling back the fiberglass. You can kind of see where the foam is on the vertical surface there.

Everyone please feel free to comment your thoughts. I guess I?m at the point where I?m about to start the major deconstruction where I start completely cutting out bulkheads and possibly the engine mount platform. Please let me know what to measure and whats the best way to take those measurements so I can get everything back in place. If the engine mount pad is still solid, should I just cut it out from the very bottom by the hull so it will be easy to fiberglass back in place?

I did figure out why so much rainwater is getting inside the cabin, I knew it was coming from the stairwell that goes down into the boat and know there is a drain hole on one of the steps to catch the water and drain it. Well, guess where that drain hole hose goes? Yep, right to the small bulkhead in the cabin just in front of the fuel tank where the cabin bilge pump sits. Obviously there?s no power to the boat/bilge pump, so it just accumulates water until I go in there and pump/vacuum it out. I?ve put a tarp over the windshield and front cockpit area at this point hoping to stop water intrusion down the stairwell.