Re: 1979 Champion Bass Boat - Tear Down and Restoration -- with PICS

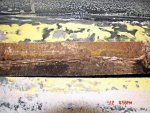

The Damage

Once it was flipped and on the dollies, we started prodding and tapping. We found any and all damage is along the inner port chine. It appears that the boat hit something hard while at moderate speed.

In this contrast-enhanced picture, you can clearly see a jagged white crack. I have marked it with a red arrow. This is about 19 inches long. Not only is the hull broken here, but the whole chine in this area is damaged. Tap down the chine with a screwdriver handle and it sounds solid until you get to this area, then it just sounds mushy.

In this next photo, also contrast-enhanced,, you can see where I have circled and marked all the damage we could find. The front circled are marked "Broken" is the area in the picture above. The area marked "Rough" is an area where the chine is solid, but it has been reshaped, apparently by hand, and it's not straight and smooth like it should be. The area marked "weak" just seems to sound different when it is tapped with a screwdriver handle. I'll have to examine it more closely once I get the black off. There was a heavy but poorly finished patch in this area when I got the boat, and I had smoothed it out before I coated the boot of the hull with Durabak. I don't remember how big it was, though. We shall see.

Question for the experts:

Should I just cut out this whole section and remold the chine? Or should I cut out only the "Broken" section, and just build up and block sand out the "Rough" area to make it straight and smooth again?

I have to be honest with everybody, and I'll point out my mistakes along the way. You see where it says, "Oops?" It seems I cut through the hull while cutting out the deck. :facepalm: At least it's a straight cut, and will be easy to fix. :redface:

One last angle on that "Weak" spot in the back. It may not be weak. It may sound different just because it is near the stern. Kinda helps give a perspective of where this chine is located.

It was a mistake to apply Durabak to the hull. I did it to stop the slow leak I had, and it worked for a couple of months. Then a day fishing on Stockton, windy day with big rough waves, opened up the leak again. Probably from the basically nonexistent stringers allowing the hull to flex and twist. That crack marked "Broken" is probably the source of the slow leak, and it's surely the place where we got it hung up on a stump, and ultimately sunk it.

So now, I tell everybody-- Don't do what I did. No shortcuts. Fix it right.