azmav

Seaman

- Joined

- Apr 16, 2013

- Messages

- 61

Re: 1984 Bayliner Capri 1600 Restoration

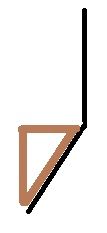

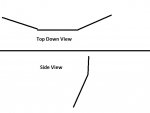

Wow, thanks all for the input and following along! I will try to keep it interesting. GT and Wood, you are both correct on the transom, I have some pictures from earlier in the project when doing my previous thread. I will include them here, as well as a quick drawing to illustrate the shape. Also, I will most definitely be going back with proper thickness of marine ply, or some variation installed all as one piece, with stringers butting up to it and lapped. I have been doing my homework here on this forum and looking to do this boat right.

RN Joe, I was thinking along those lines this morning. As GT mentioned, there is Seacast, and then Nida Bond from the company that makes NIdacore, the honeycomb panels. But looking top down over the stern of the boat, I am certain that I can make ply fit into where I need it.

Further, looking over your pictures, it is surprising the similarities! The original work on this boat was pretty poor though and only one stringer used the knee bracing. The opposite stringer on the port side ended at a bulkhead at the bilge area, and then the bulkhead stepped the structural support over a few inches into the same panel that can be seen in the second picture.

Wow, thanks all for the input and following along! I will try to keep it interesting. GT and Wood, you are both correct on the transom, I have some pictures from earlier in the project when doing my previous thread. I will include them here, as well as a quick drawing to illustrate the shape. Also, I will most definitely be going back with proper thickness of marine ply, or some variation installed all as one piece, with stringers butting up to it and lapped. I have been doing my homework here on this forum and looking to do this boat right.

RN Joe, I was thinking along those lines this morning. As GT mentioned, there is Seacast, and then Nida Bond from the company that makes NIdacore, the honeycomb panels. But looking top down over the stern of the boat, I am certain that I can make ply fit into where I need it.

Further, looking over your pictures, it is surprising the similarities! The original work on this boat was pretty poor though and only one stringer used the knee bracing. The opposite stringer on the port side ended at a bulkhead at the bilge area, and then the bulkhead stepped the structural support over a few inches into the same panel that can be seen in the second picture.