Ciera2450

Lieutenant Junior Grade

- Joined

- Apr 8, 2011

- Messages

- 1,049

Well, a bit more sanding and the engine stringers will be ready for a coat of rain before PB’ing them in place and glassin.

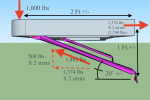

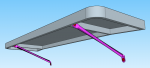

I have drilled the drain hole in each near the aft end that will hold a pvc drain tube. I took these pics before I drilled out the hole. I drilled them so the pvc pipe is flush with the bottom edge. In one of the pics below, you can really see the funky curves and angles to get them to sit right against the hull. Fwd n aft ends of them butt against the new transom and bulkhead fillet curves. I used the DA sander and just kept test fitting them through he keyhole until they sat properly. The midsections sat nice and flat once the ends were sanded to shape. I have a jig made up to hold them in place and a bit off the hull while PB’ing them in. Waiting on enough resin...

I just placed my order with USC for 3 more gallons of resin and a gallon of gelcoat. Think a Gallon should be enough gel to do the whole engine bay and floor of berth area?

After these stringers are glassed in, I will go through the entire engine bay with grinder/sander to prep for the gelcoat. . I’d also like to touch up some areas on the exterior transom and will likely need to color match.... crap, I didnt order any pigment. I know my exterior gel is not the super bright white the USC gel is.

Gonna run out and get a coat of resin on these engine mounts and maybe PB any voids if I have enough resin.

7D8A5D76-487A-4F76-8B3C-E52683A4260F by Ciera 2450, on Flickr

7D8A5D76-487A-4F76-8B3C-E52683A4260F by Ciera 2450, on Flickr

5D5372B5-CDBF-4C94-8BFF-FB0E0DED553E by Ciera 2450, on Flickr

5D5372B5-CDBF-4C94-8BFF-FB0E0DED553E by Ciera 2450, on Flickr

B5D99558-956A-46F0-84FF-F5D30B9B1F66 by Ciera 2450, on Flickr

B5D99558-956A-46F0-84FF-F5D30B9B1F66 by Ciera 2450, on Flickr

I have drilled the drain hole in each near the aft end that will hold a pvc drain tube. I took these pics before I drilled out the hole. I drilled them so the pvc pipe is flush with the bottom edge. In one of the pics below, you can really see the funky curves and angles to get them to sit right against the hull. Fwd n aft ends of them butt against the new transom and bulkhead fillet curves. I used the DA sander and just kept test fitting them through he keyhole until they sat properly. The midsections sat nice and flat once the ends were sanded to shape. I have a jig made up to hold them in place and a bit off the hull while PB’ing them in. Waiting on enough resin...

I just placed my order with USC for 3 more gallons of resin and a gallon of gelcoat. Think a Gallon should be enough gel to do the whole engine bay and floor of berth area?

After these stringers are glassed in, I will go through the entire engine bay with grinder/sander to prep for the gelcoat. . I’d also like to touch up some areas on the exterior transom and will likely need to color match.... crap, I didnt order any pigment. I know my exterior gel is not the super bright white the USC gel is.

Gonna run out and get a coat of resin on these engine mounts and maybe PB any voids if I have enough resin.

7D8A5D76-487A-4F76-8B3C-E52683A4260F by Ciera 2450, on Flickr

7D8A5D76-487A-4F76-8B3C-E52683A4260F by Ciera 2450, on Flickr 5D5372B5-CDBF-4C94-8BFF-FB0E0DED553E by Ciera 2450, on Flickr

5D5372B5-CDBF-4C94-8BFF-FB0E0DED553E by Ciera 2450, on Flickr B5D99558-956A-46F0-84FF-F5D30B9B1F66 by Ciera 2450, on Flickr

B5D99558-956A-46F0-84FF-F5D30B9B1F66 by Ciera 2450, on Flickr