BreamBass&Beyond

Recruit

- Joined

- Apr 12, 2021

- Messages

- 3

Hi everyone,

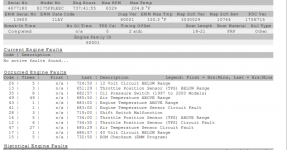

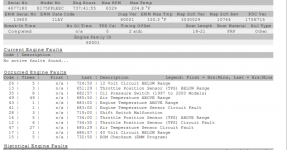

I have a 1999 evinrude ficht 175 hp model # E175FPLEEC. The boat cranks up good the first time, every time and runs well to the first two or so spots that I run to. The problem usually starts on about the 3rd good run of the day that I make. Sometimes when up to speed on this run the engine will jerk as if I hit something and go dead, other times it will jerk like I hit something but not die and continue running as if nothing ever happened until a little while later when the issue repeats itself. In the instances that it does die when this happens I can crank it right back up and again it will run like nothing ever happened. No alarms are sounding when it does this. This week I purchased the evinrude diagnostic software and bootstrap to see if there were any stored codes and attached is what I got. I think that code 26 has been resolved since it hasn't occurred since I replaced an old battery that was going bad. I also believe that the tps codes are a result of me starting the engine with the tps unhooked by mistake a few times. Do any of these codes seem like they could be causing my issue? Should I be alarmed by any of these or should they all be relatively easy fixes? I plan on taking my laptop out with me and seeing if I can see what code, if any throws when this happens.

I have a 1999 evinrude ficht 175 hp model # E175FPLEEC. The boat cranks up good the first time, every time and runs well to the first two or so spots that I run to. The problem usually starts on about the 3rd good run of the day that I make. Sometimes when up to speed on this run the engine will jerk as if I hit something and go dead, other times it will jerk like I hit something but not die and continue running as if nothing ever happened until a little while later when the issue repeats itself. In the instances that it does die when this happens I can crank it right back up and again it will run like nothing ever happened. No alarms are sounding when it does this. This week I purchased the evinrude diagnostic software and bootstrap to see if there were any stored codes and attached is what I got. I think that code 26 has been resolved since it hasn't occurred since I replaced an old battery that was going bad. I also believe that the tps codes are a result of me starting the engine with the tps unhooked by mistake a few times. Do any of these codes seem like they could be causing my issue? Should I be alarmed by any of these or should they all be relatively easy fixes? I plan on taking my laptop out with me and seeing if I can see what code, if any throws when this happens.