Hi guys,

I recently bought this small 12 feet boat, only to find out days later that the transom was completely rotten.

It had been repaired twice earlier I could see. First they put an additional plywood plate on the inside and glassed it in, later when that started to give in, they put a plate on the outside too.

So I removed the top and cut off a piece of the floor in the back end, so I would have sufficient working space to remove the old transom and insert a new one, aswell as inspect the stringers.

It turned out the stringers were pure fibreglass, however they were detached from the hull of the boat (see one of the pictures, I could lift it with my finger), again really bad glassing work, I could peel of the glassing they had layed onto the sides of the stringers with my hands, also it was a clear sign that the floor had been removed before and a repair of somekind had been made.

I suspect that there was originally foam in the boat, that had gotten wet and someone pulled the floor up and stringers aswell and removed all the foam.

Afterwards they simply glassed the stringers back on. Made some drains and closed the floor again. It's just a theory as I did not see any traces of foam anywhere, but the stringers are quite thin and the buttom of the boat isn't exactly very thick either.

For now I have epoxied a new transom in and just finished giving it 3 layers of glassfibres (after reading a ton of threads on here), so now it's time to move onto the stringers, however it seems most boats on here have wood stringers that are glassed in.

- I am not sure how to deal with them, so I could need some the expert advice.

My plan is to glue the stringers back on with epoxy (after grinding and cleaning), then cut the top off them and give them 2-3 layers of glassing on each of the sides attaching them to the hull, afterwards I would fill the stringers with 2 component foam and glass the top back on. I'd fill the rest of the buttom with foam aswell, then epoxy the floor back on (needing to replace the plywood plate on that first though).

Does this sound like the proper way to do it? -Also as I am not sure if there was originally foam in this boat, is it possible it was build like this without foam?

Here is a some pictures, so you can see what I am talking about.

As she looked before I started:

After the floor was cut out:

Deck, stringers and floor:

New transom glued in 2 layers of 3/4 inch plywood after adding 3 layers of glass first, as the end was very thin after grinding out the remains of the rotten wood:

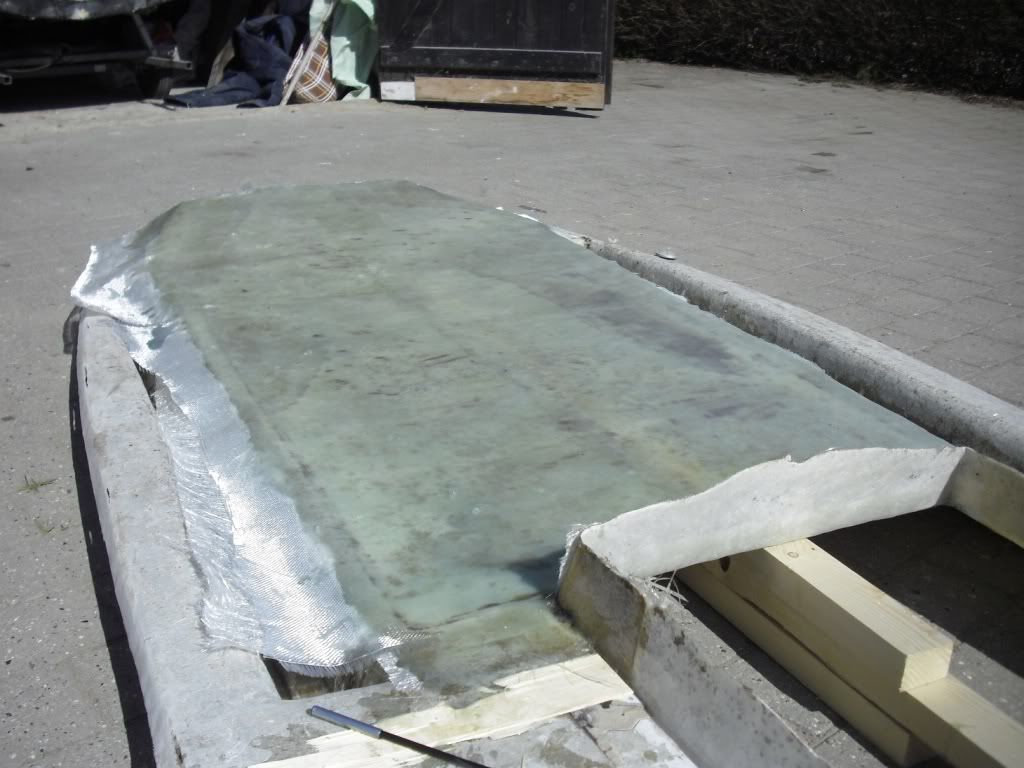

New transom glassed with 3 layers, keeping the temperature right:

Any input or advice greatly appreciated.

Regards,

CP.

I recently bought this small 12 feet boat, only to find out days later that the transom was completely rotten.

It had been repaired twice earlier I could see. First they put an additional plywood plate on the inside and glassed it in, later when that started to give in, they put a plate on the outside too.

So I removed the top and cut off a piece of the floor in the back end, so I would have sufficient working space to remove the old transom and insert a new one, aswell as inspect the stringers.

It turned out the stringers were pure fibreglass, however they were detached from the hull of the boat (see one of the pictures, I could lift it with my finger), again really bad glassing work, I could peel of the glassing they had layed onto the sides of the stringers with my hands, also it was a clear sign that the floor had been removed before and a repair of somekind had been made.

I suspect that there was originally foam in the boat, that had gotten wet and someone pulled the floor up and stringers aswell and removed all the foam.

Afterwards they simply glassed the stringers back on. Made some drains and closed the floor again. It's just a theory as I did not see any traces of foam anywhere, but the stringers are quite thin and the buttom of the boat isn't exactly very thick either.

For now I have epoxied a new transom in and just finished giving it 3 layers of glassfibres (after reading a ton of threads on here), so now it's time to move onto the stringers, however it seems most boats on here have wood stringers that are glassed in.

- I am not sure how to deal with them, so I could need some the expert advice.

My plan is to glue the stringers back on with epoxy (after grinding and cleaning), then cut the top off them and give them 2-3 layers of glassing on each of the sides attaching them to the hull, afterwards I would fill the stringers with 2 component foam and glass the top back on. I'd fill the rest of the buttom with foam aswell, then epoxy the floor back on (needing to replace the plywood plate on that first though).

Does this sound like the proper way to do it? -Also as I am not sure if there was originally foam in this boat, is it possible it was build like this without foam?

Here is a some pictures, so you can see what I am talking about.

As she looked before I started:

After the floor was cut out:

Deck, stringers and floor:

New transom glued in 2 layers of 3/4 inch plywood after adding 3 layers of glass first, as the end was very thin after grinding out the remains of the rotten wood:

New transom glassed with 3 layers, keeping the temperature right:

Any input or advice greatly appreciated.

Regards,

CP.

Last edited by a moderator: