Re: Went to get some supplies , now iam lost again .

Re: Went to get some supplies , now iam lost again .

Just when i begin thinking , can i really do this , someone chimes in . I really do thank you for that .

I fiqured i need to get somewhat of a plan together.

Had a friend come over and since i still had access to get under the boat , i used posterboards taped together and follwed the line from the underside that the stringer sits in . ( just in case the stringer breaks apart , i can fall back to this and also opps post on scribe method )

My trailer has bunks but not real long so we made some temps one just to be safe . I checked the stringer height at 1 foot intervals , but also noticed the stringer in most places is not even to where the deck would sit . The back of stringer is about 1/2 inch low and up to the front is about 7/16 th inch to high. Is this something to worry about now or just make the stringer slightly taller and trim it down later ?

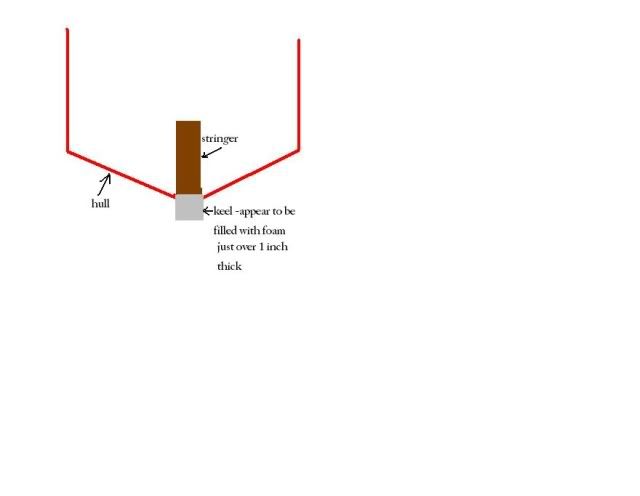

We removed a section of the stringer to see what i would be dealing with . Sure enough the stringer was sitting of foam . I don't think this part will be to bad to clean up , but man look at the sanding i got ahead of me to be able to glass the new stringer in . I will need to fill this area full of Pl so its even with the hull correct ? Few pics below .

The basic plan is below

#1) remove the stringer then replace the stringer and finish this part before anything else . The stringer does not goto the transom , so at this point i will move to next step.

#2)remove the motor , flip the boat and do some minor underside work . Build a cradle , flip the boat onto the cradle .

#3) remove the rest of the floor ( livewells and ect. )

#4) start transom removal and rebuild , then install deck