Re: 8000 lb cruiser twin merc 260's

Smoke, I hate to say it because last time I brought this up it was like I insulted the "gods of boating" or something, but I think one of the problems you're having with your prop dilemma is caused by the vast majority of people not understanding how power, gearing (propping), and drag are related.

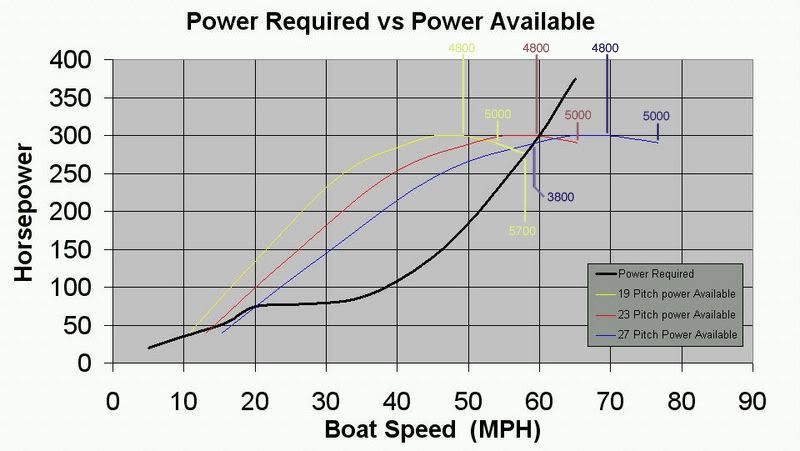

Manufacturers (and almost all the internet "prop gurus") recommend that you prop your boat so that it reaches its top speed at maximum engine RPM. This is a good all-around compromise but is optimized for nothing but top speed. It also keeps people who don't understand what they're doing from burning up their motors thus is a smart move by the manufacturer so they don't have to replace motors under warranty. It?s also easy to do because all it takes is a speedometer and tachometer. This is what you?re seeing in all the recommendations. This operating parameter is taken as gospel. Although it is an EXCELLENT all-around, general recommendation that will keep the general public from over-revving OR under-revving their engine under normal use, it will not give you the optimum pitch for either acceleration or efficiency. With a fixed pitch prop and a single speed transmission, you can only optimize one thing. You have to choose between acceleration, top speed, and efficiency.

If you optimize for top speed, you don't give up significant losses in acceleration or efficiency and don't risk engine damage caused by under-revving or over-revving. For pulling up skiers, lower powered boats that may be marginal on power will often choose to not optimize for top speed, but to use a lower pitched prop that optimizes their acceleration at the expense of top speed.

Propped as generally recommended, your boat will reach its max top speed and you will not risk damaging your engine. However, your

acceleration will not be optimal. To optimize acceleration you have to run a smaller prop (like 1st gear in a car) and accept the risk of over-revving the motor if you try to operate at sustained high speeds.

Propped as generally recommended, your

cruise efficiency will also not be optimal. To optimize your cruise efficiency you have to run a bigger prop (like overdrive in a car) and accept the risk of under-revving the motor if you try to operate at sustained low speeds. However, due to the much higher drag of water as opposed to air, the gains to be made are minimal compared to the risks of high engine loads if you operate the engine below cruise conditions.

The manufacturer?s recommendations are the equivalent of gearing your car so that it reaches top speed in its highest gear. Only problem is that most boats only have one gear, unless you run a variable pitch prop or are into over 100 MPH water ski racing, like this boat (NWSRA is National Water Ski Racing Association):

FOR SALE

NWSRA Boat #471. 21' Hallett. 3A outdrive. 510 cu turbo Chevy by Power Marine. Over 1000 hp. Turbo 400 tranmission. Newer trailer. $20,000 or make offer. Contact Dave Allen at 541-312-8305

Notice that it has a Turbo 400 transmission in it. This is because the water ski racers need to optimize acceleration AND top speed. You can't do both without a variable-pitch prop or a transmission, and I don't know of any variable-pitched props sized to handle 1000 HP.

In the automotive world, where powertrains that are designed for speed ALSO have to meet government efficiency standards, you?ll find that efficient, higher powered cars are NOT CAPABLE of reaching their maximum RPM or top speed in the highest gear. Top gear is a very high overdrive gear used only for gas mileage and cruising. You?ll find that you have maximum acceleration in the lower gears (hopefully this is obvious to everybody), maximum speed where the power peak coincides with the drag curve (not necessarily in top gear), and maximum efficiency where the engine is turning as slow as it can (overdrive) and still deliver the HP required due to drag.

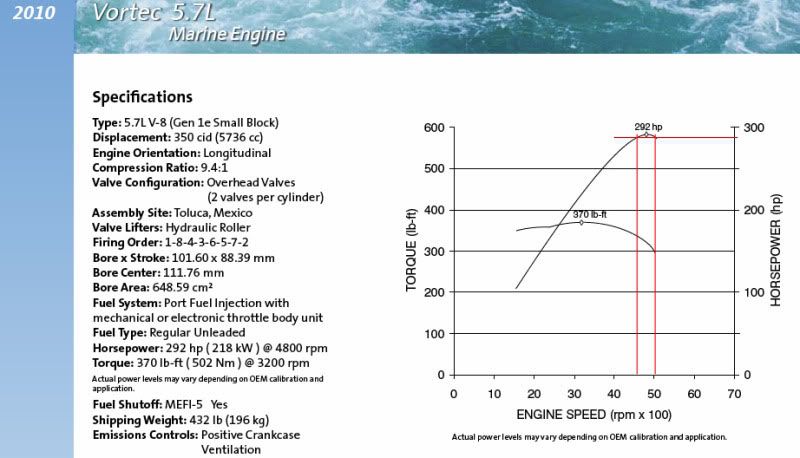

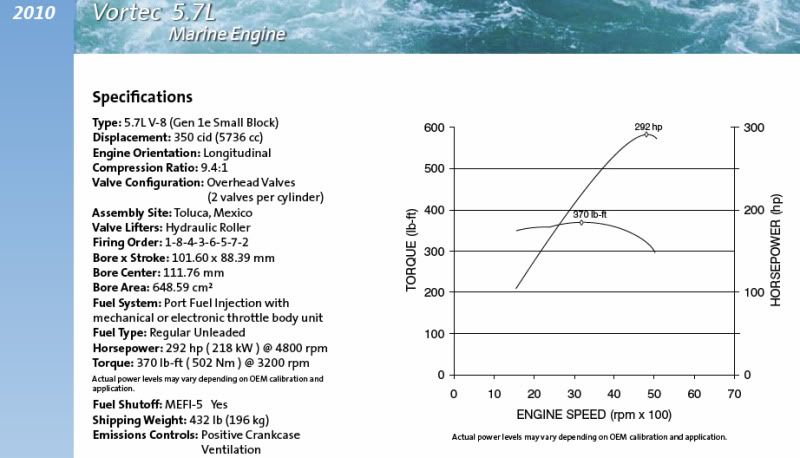

For example, a Z06 Corvette has maximum efficiency (24 MPG) at 1400 RPM at 65 MPH in 6th gear. It generates maximum horsepower (505 HP) at 6300 RPM. If it could rev to its HP peak in top gear it could do 292 MPH. Unfortunately, the power required due to drag exceeds the power available from the engine in 6th gear at 180 MPH (3900 RPM) so it can?t turn any more RPM or go any faster in 6th gear. However it's top speed is 198 mph. Top speed is achieved in 5th gear at 6300 RPM where the power available peak (505 HP) coincides with the power required (due to drag) curve. The same thing happens in boats, except that it is much more exaggerated because of the higher drag of water as opposed to air. To begin to understand how it works you need to be familiar with the basic principles in this thread:

http://forums.iboats.com/showthread.php?t=225803&highlight=secrets

which shows an under-propped (acceleration) case, a normally (general public ? top speed) propped case, and an over-propped (efficiency) case. The problem with the over-propped case is that while your boat will be more efficient at a certain speed, your top speed will be slower than it could be and you are risking over-loading and damaging your engine under sustained operation at lower speeds.

Your boat is like a car with an automatic transmission in which you have a choice of one gear to lock the car into (the propellor in the water is analogous to the torque convertor). What this means in boating is that if you prop your boat for max efficiency it would be like locking your car in overdrive. If you're driving in the city in stop and go traffic with a max speed of 10 MPH, you're going to be lugging your engine horrendously and fry it real quick. You'd be better off locking it in first gear.

However, if you want to drive from Florida to California, going 15 MPH with the engine screaming at maximum RPM in first gear will kill it quick. If you're only accelerating from a stop once or twice a day, you'd be better off locking it in overdrive and cruising 70 MPH at 1500 RPM all day.

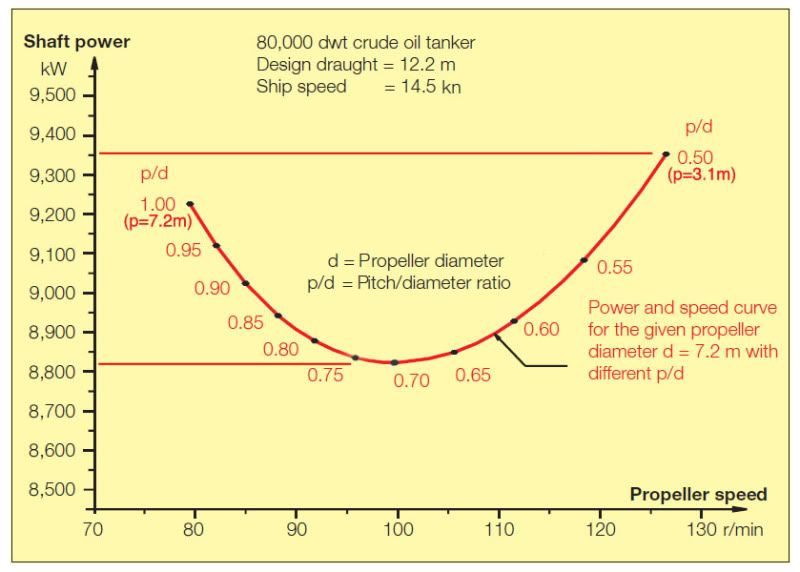

To finally get to your prop diameter question, you'll find that if you propped your boat for

maximum efficiency as opposed to

maximum top speed, you'd be using a bigger diameter, high pitch prop that would be incapable of reaching the recommended maximum RPM of your engine (just like overdrive in a car), because the additional drag due to the bigger diameter increases exponentially at higher speeds and RPMs. You will also pi$$ off all the prop gurus and they will talk bad about you. If you were to use that prop for sustained operation below cruise, or for skiing, or pulling tubes, it would be like driving your car around town locked in overdrive. As a general rule, the disadvantages would FAR outweigh the advantages. A manufacturer that propped a boat like that would be replacing engines under warranty left and right. Anybody that recommended it would have people crying at them that they burned up their motor. But if you plan to get in your boat and cruise at 25-30 MPH for 4 or 5 hours, the big prop would give you higher efficiency, and the additional load on the engine as it accelerates to cruising speed once or twice a day would be insignificant.

The only way I know to optimize cruise like this is with a GPS, a fuel flow meter, and experimenting with different props. And once you do, I would imagine that the gains you would see would be in the ?couple of percent? range at best as opposed to using the ?normal? or recommended propping, due to the inherently high drag of water as opposed to air. It doesn?t make sense to me to worry about it with such minimal gains. Prop it so it reaches max speed at max RPM and be done with it.

My boat is 23 years old and has 600 hours on it, and I would estimate that at least half of those were spent idling around at ?no-wake? speeds. 20 gallons/hour is supposedly the fuel burn rate at most efficient cruise on my boat. That?s cruising at a speed in the low 20?s so it?s getting better than 1 MPG. 300 hours at 20 GPH is 6000 gallons burned at cruise. So if the original owner had put a set of ?efficiency? props on it and saved 2% in cruising fuel, it would have saved 120 gallons in 23 years. It wouldn?t even have offset the cost of the set of props.

Given the size, weight, and speed range of our boats, I wouldn?t be surprised that if you went with twin Bravo II?s and bigger diameter props, then any efficiency gains you see from the bigger diameter would be offset by the additional drag of the prop and the additional drag of the bigger lower units.

Traditionally here we?ve had very cheap fuel prices relative to our income. Its been proven over the years that for our small, recreational planing boats the smaller, higher RPM props give up a little performance at acceleration and give up a little efficiency at cruise, but don?t risk frying the engine and thus are the best choice for all-around usage. Its always been very common to swap on a smaller prop for more acceleration. Don?t be surprised in the future to see some re-thinking on prop sizes as fuel becomes more expensive.