Re: 8000 lb cruiser twin merc 260's

45Auto, I know that my analysis works very well and DOES come up with answers that are very very close to REALITY.

45Auto Post 51

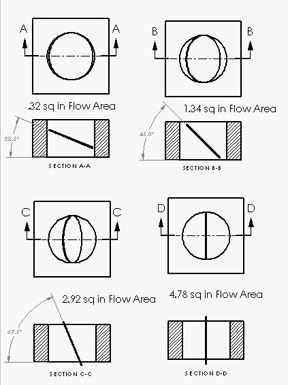

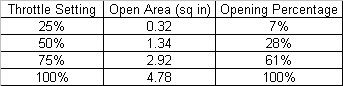

In other words, pretty much NOTHING to do with fluid flows (water or air, props or carburetors) is linear. All I see in your spreadsheets is straightforward linear RPM relationships.

That is because they ARE linear relationships, I used 10% prop slip for all of my calculations, which reduces the fluid dynamics and boat drag coefficient errors involved in the analysis .

45Auto Post 51

Look at the oil tanker p/d diagram in my previous post #30. They kept everything the same except the prop pitch. They cut the pitch in half (from 24 feet to 12 feet) while maintaining the same vessel speed of 14 knots. If you ran these numbers in your spreadsheet it would show that the prop RPM would double. Just like if you run it with a 19" pitch and a 38" pitch at 59 MPH it will show the 19" pitch prop RPM will be double that of the 38" pitch RPM.

However, as you can tell from the tanker diagram, in the real world the prop RPM did NOT double. It was 80 RPM with the 24' pitch at 14 knots, your prediction would have been 160 RPM with the 12' pitch at 14 knots. In the real world the 12' pitch only turned about 125 RPM, only about a 50% increase instead of the 100% increase you would have predicted.

But, if you will notice on EVERY prop pitch change I made in these posts I use the SAME EXACT 10% prop slip for EVERY prop, that is why I can use Linear math. The closer the pitch is between any two props that are being exchanged, the closer my analysis is to the exact speed and RPM that can be expected by changing pitches, in the same make and model of prop. 95% of all prop changes needed in this forum are 4" or less and it is normally only 2".

I went to Mercury's website and ran the numbers you gave above on the tanker and these are there results, and they are the same as mine, if you use the same 26% prop slip for all props, the way I use 10% for my prop analysis.

If anyone would care to verify this data just go to Merury's Prop Slip page and input the same data and solve for % of prop slip.

Here is the browser address:

http://www.mercuryracing.com/propellers/propslipcalculator.php

24' Pith and 80 RPM 26% Prop Slip 16 MPH

12' Pitch and 160 RPM 26% Prop Slip 16 MPH

12' Pitch and 125 RPM 26% Prop Slip 13 MPH

12' Pitch and 125 RPM 6% Prop Slip 16 MPH

In order for this prop to attain the 16 MPH at 125 RPM, the prop slip has to drop to 6% at those rpm. And since the diameter is constant and NOT VARIABLE like our props (as Pitch goes up Diameter goes down), in any particular make and model of our props. It is NOT comparable to the props we use on our boats, as it is a constant Diameter prop that is rotated about its axis to mechanically change pitches. And it is NOT comparing apples to apples.

45Auto Post 51

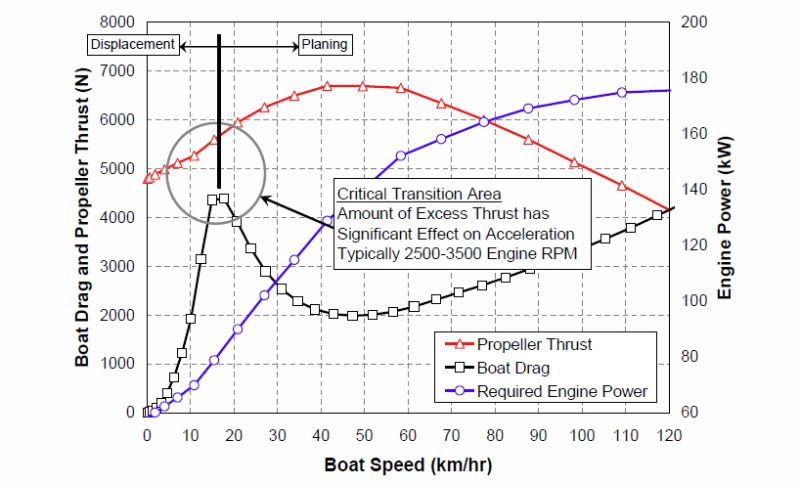

I?ll be busy the next couple of days, I?ll try to put something together this weekend. But if you want to add RPM to the ?Power Required vs Power Available? graph, it?ll look something like the one below, NOT what you did. Each pitch would require it's own RPM scale on the same axis as speed. I added them below at the max HP point and the point where each prop runs out of power against the power available curve. You can see that the 19" pitch would do about 57 MPH, the 23" pitch about 59 MPH and the 21" pitch about 61 MPH. It would have been easier to explain with a separate graph for each pitch before I combined them, but we're limited by the forum constraints.

hwsiii Post 36

Prop Speeds with 10% Prop Slip

I notice NOWHERE in your Motor and Prop curve analysis is Fluid Dynamics or Aerodynamics used, does that mean your results are less acceptable, I don't think so.

I also see that two of my numbers using my Linear Math are also within about 3% of your numbers while the middle one is dead on, and your numbers are not exact.

And that is while we are using an 8" difference in pitch, which is an actual increase in pitch of 42%. These props jump from 19" to 27" in pitch, so

I think anyone would have to say my method works very well when comparing it to yours.

Whether either one of us uses Fluid Dynamics or Aerodynamics does not matter.

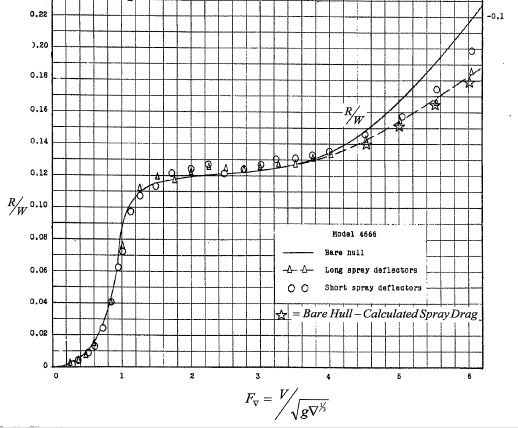

I DO agree that my numbers are not EXACT, but if you are willing to spend the time and effort, and also have the people coming to this forum collect ALL the information required to run a FULL analysis using fluid dynamics and the correct drag coefficients for their boat and motor, more power to you. I have all of Savitsky's equation's, except Whisker spray drag, in an Excel spread sheet, but most people that come in here are certainty NOT willing or knowledgeable enough to give me ALL the information required to fill this out to see what speed they should be able to attain with their boat and motor, and even if they did it would only be good at ONE angle of thrust only, because Savitsky's formulas all assume that the boat has an INBOARD motor that NEVER changes the angle of thrust but instead uses trim tabs to change the running angle of the boat, and it can only bring the bow down and not up, while our outboard and inboard/outboard motors ARE able to bring the bow up or down, which in turn means we are able to maximize our speed and RPM.

Do YOU have ALL the power curves required to do an analysis of all the different motors and boats that people ask about on here, NO of course you don't, so you are ONLY able to to do it on motors that you have the CORRECT power curves for. Doing it without the true power curves is just like what I do here,

the best approximation you can come up with. I do my best to educate people on here and give them more knowledge about props than they had before they came here so they can make more intelligent decisions and have more knowledge than they had before they entered this forum, and I am very happy with the results that I have seen.

I have posted my required information questions on here MANY MANY times and NEVER gotten a response from the person inquiring about what prop they need, because they don't know the information I am asking for and are not willing to spend the time required to find it. Some have even asked me "Are You For REAL". But, I don't mind, because if they are willing to

try, and expend the effort required to find a better prop for their boat, then I am willing to do my best to help them.

H