fire7882

Petty Officer 2nd Class

- Joined

- Jul 15, 2008

- Messages

- 172

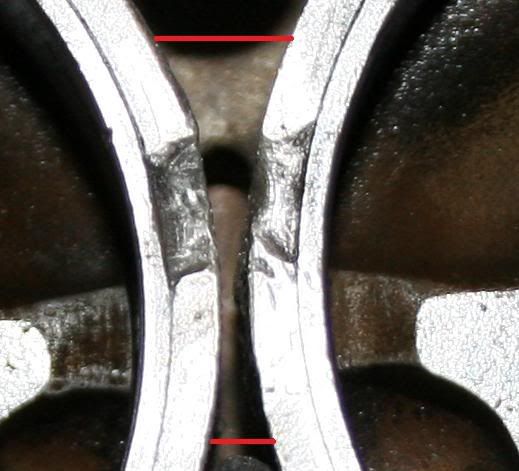

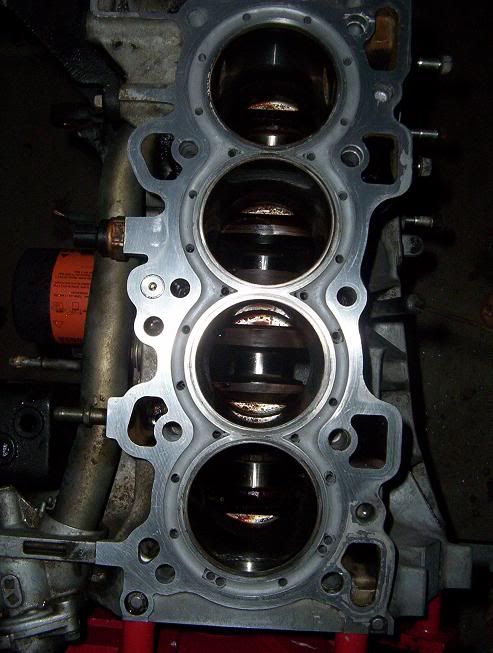

The previous owner must have gotten really mad at this motor and decided that taking a hammer to it would cure all his frustrations. After cleaning various parts, I got out a razor and started removing the old gaskets from the power head. I soon noticed the starboard side cylinders have dints and gouges everywhere between the head and block mating surfaces. Worst of all, the outer surface of the cylinders are missing a small chunk of metal.

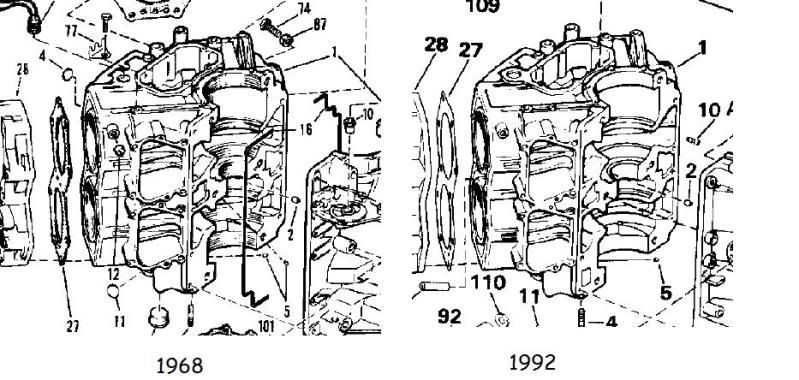

I'm not sure where to go from here. The PO had the voids filled with JB weld and the compression was fine so I might do the same for the time being. I'll be keeping an eye out for a good yet affordable power head but still plan to piece this one back together. I have a 1964-65 evinrude 90 hp OB that I'm hoping has the same block as this one. Even though I doubt it does, I'll use the possessed power head until I can get the 64-65 block rebuilt. Below is a picture comparing a 1968 block to a 1992 block. The evinrude parts catalog didn't go back to 1965.

My restoration thread

http://forums.iboats.com/showthread.php?t=265171

Any suggestions or advise is greatly appreciated.

I'm not sure where to go from here. The PO had the voids filled with JB weld and the compression was fine so I might do the same for the time being. I'll be keeping an eye out for a good yet affordable power head but still plan to piece this one back together. I have a 1964-65 evinrude 90 hp OB that I'm hoping has the same block as this one. Even though I doubt it does, I'll use the possessed power head until I can get the 64-65 block rebuilt. Below is a picture comparing a 1968 block to a 1992 block. The evinrude parts catalog didn't go back to 1965.

My restoration thread

http://forums.iboats.com/showthread.php?t=265171

Any suggestions or advise is greatly appreciated.