Okay, so I am preparing for my rebuild this winter and have been reading every 16-19ft glass rebuild on this forum I can. I understand what the pros and cons of epoxy vs. poly and yes Chrishayes, I know you will say to use poly  which is what I am leaning towards. The big question I have to prepare financially for what my 'black hole' will require is HOW MUCH? I am figuring on 15 gallons for the transom, 3 stringers, and deck? Is this about right? Any issues with US Composites? Also, since I am probably going poly I was thinking of getting a gallon of epoxy to use between the transom layers, but nowhere else. I have read that some people use PL and no matter what I do it will be better than stock (no glass on the inside of the transom, just paint.

which is what I am leaning towards. The big question I have to prepare financially for what my 'black hole' will require is HOW MUCH? I am figuring on 15 gallons for the transom, 3 stringers, and deck? Is this about right? Any issues with US Composites? Also, since I am probably going poly I was thinking of getting a gallon of epoxy to use between the transom layers, but nowhere else. I have read that some people use PL and no matter what I do it will be better than stock (no glass on the inside of the transom, just paint.

I am also completely stuck on splitting the hull or not? I have a closed bow with gas tank underneath and I want to replace it as well as build in some front battery storage, and front ballast tanks, but this boat must be on the water May 2010 and I will be starting mid October. I have already seen a rebuild on classic Glastrons forum and I do not have to split the hull for the floor, stringer, transom. If you need pictures of the boat please see this post: http://forums.iboats.com/showthread.php?t=335793

Thanks again for the help.

Cliff Notes: some questions not yet answered

1. Epoxy Vs. Poly (system-f)

2. How much resin for a 17ft runabout? (System-f)

3. US Composites OK? (System-f)

4. What exactly is the right prep.? To acetone or not to acetone? (adamjr)

5. What can go directly on wood, cloth? CSM? Biaxle? (System-f)

6. Water on fresh glass? ( Redfury)

Epoxy Vs. Poly

Epoxy is too expensive. (Drewpster)

Poly adhesion problems can be handled with proper prep. (Drewpster)

Poly requires extra personal protection, tyvek suit, respirator, keep it warm in winter. (Chrishayes)

Poly will work just fine as long as you prep. Properly (Chrishayes)

Don?t worry too much about resin type just DO NOT mix types (Bronc Rider)

epoxy is suppose to be stronger then poly. Also, epoxy is a little forgiving for a beginner however, terrible when wetting out matt.(Bigredinohio)

Amount of Resin

15-20 gallons (drewpster)

Maybe only 12 gallons (Chrishayes)

Us Composites

Great company! (Chrishayes)

What exactly is the right prep?

Grinding and follow up with a broom then clean with acetone (Bronc Rider)

Must use acetone, is cheap and good insurance for a clean surface (Chrishayes)

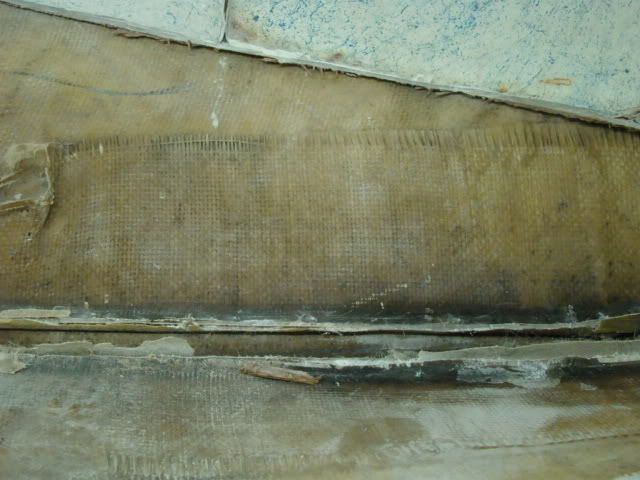

Proper grinding to good glass is key. (Chrishayes)

Acetone is an ionic bridge and can help carry resin deeper into the surface being bonded. (jonesg)

Must get to clean glass, must clean with acetone. (redfury)

Not enough grinding = no good bond, too much and you are through the hull (Chrishayes)

Acetone is not necessary because you should have ground off all of the contaminated layers (Bronc Rider)

You need clean glass before you can lay up. (Bronc Rider)

Can tell a difference in surface cleanliness when using acetone (Chrishayes)

It is not wrong to use Acetone, just not necessary all of the time and cause problems if it doesn?t evaporate completely. (Bronc Rider)

Grinding fiberglass sucks (everyone)

Acetone no good because you are just spreading around the mess and it leaves a thin film (ondarvr)

Acetone causing tac in old glass can be bad, this also weakens the area (Bronc Rider)

What can go directly on wood, cloth? CSM? 1708? (System-f)

unanswered

Water on fresh glass?

It depends on the state of cure when the water came in contact with it. A firm laminate will have a slight amount of the resin on the surface turn white from the water. A soft (uncured) laminate will let the water penetrate deeper, the softer it is, the deeper the water will go. In all cases the contaminated resin (white) will need to be removed if more glass is going to be applied over it. If the laminate was cured and there was a slight amount of discoloration on the surface and you don't need to glass over it, then there is no problem, just leave it as is.

Grinding a Boat Equipment and Information

Safety

Respirator ? a real one, the 3m with pink filters

Goggles ? covers the entire face, not safety glasses

Ear plugs or muffs

Tyvec suit

Rubber gloves

Masking tape ? to tape cuffs to gloves.

Tools

Heavy duty Grinder

4 ?? Grinder

Straight die grinder or rotozip

I am also completely stuck on splitting the hull or not? I have a closed bow with gas tank underneath and I want to replace it as well as build in some front battery storage, and front ballast tanks, but this boat must be on the water May 2010 and I will be starting mid October. I have already seen a rebuild on classic Glastrons forum and I do not have to split the hull for the floor, stringer, transom. If you need pictures of the boat please see this post: http://forums.iboats.com/showthread.php?t=335793

Thanks again for the help.

Cliff Notes: some questions not yet answered

1. Epoxy Vs. Poly (system-f)

2. How much resin for a 17ft runabout? (System-f)

3. US Composites OK? (System-f)

4. What exactly is the right prep.? To acetone or not to acetone? (adamjr)

5. What can go directly on wood, cloth? CSM? Biaxle? (System-f)

6. Water on fresh glass? ( Redfury)

Epoxy Vs. Poly

Epoxy is too expensive. (Drewpster)

Poly adhesion problems can be handled with proper prep. (Drewpster)

Poly requires extra personal protection, tyvek suit, respirator, keep it warm in winter. (Chrishayes)

Poly will work just fine as long as you prep. Properly (Chrishayes)

Don?t worry too much about resin type just DO NOT mix types (Bronc Rider)

epoxy is suppose to be stronger then poly. Also, epoxy is a little forgiving for a beginner however, terrible when wetting out matt.(Bigredinohio)

Amount of Resin

15-20 gallons (drewpster)

Maybe only 12 gallons (Chrishayes)

Us Composites

Great company! (Chrishayes)

What exactly is the right prep?

Grinding and follow up with a broom then clean with acetone (Bronc Rider)

Must use acetone, is cheap and good insurance for a clean surface (Chrishayes)

Proper grinding to good glass is key. (Chrishayes)

Acetone is an ionic bridge and can help carry resin deeper into the surface being bonded. (jonesg)

Must get to clean glass, must clean with acetone. (redfury)

Not enough grinding = no good bond, too much and you are through the hull (Chrishayes)

Acetone is not necessary because you should have ground off all of the contaminated layers (Bronc Rider)

You need clean glass before you can lay up. (Bronc Rider)

Can tell a difference in surface cleanliness when using acetone (Chrishayes)

It is not wrong to use Acetone, just not necessary all of the time and cause problems if it doesn?t evaporate completely. (Bronc Rider)

Grinding fiberglass sucks (everyone)

Acetone no good because you are just spreading around the mess and it leaves a thin film (ondarvr)

Acetone causing tac in old glass can be bad, this also weakens the area (Bronc Rider)

What can go directly on wood, cloth? CSM? 1708? (System-f)

unanswered

Water on fresh glass?

It depends on the state of cure when the water came in contact with it. A firm laminate will have a slight amount of the resin on the surface turn white from the water. A soft (uncured) laminate will let the water penetrate deeper, the softer it is, the deeper the water will go. In all cases the contaminated resin (white) will need to be removed if more glass is going to be applied over it. If the laminate was cured and there was a slight amount of discoloration on the surface and you don't need to glass over it, then there is no problem, just leave it as is.

Grinding a Boat Equipment and Information

Safety

Respirator ? a real one, the 3m with pink filters

Goggles ? covers the entire face, not safety glasses

Ear plugs or muffs

Tyvec suit

Rubber gloves

Masking tape ? to tape cuffs to gloves.

Tools

Heavy duty Grinder

4 ?? Grinder

Straight die grinder or rotozip

Last edited: